|

ac30zn00001354

ELECTRONIC SPARK ADVANCE CONTROL [SKYACTIV-X 2.0]

id0140hf188200

Outline

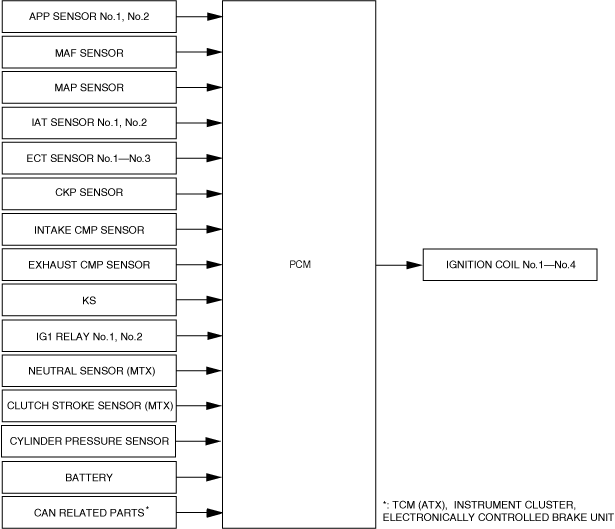

Block Diagram

ac30zn00001354

|

Operation

Ignition method

Timing chart

am3zzn00010098

|

Determination of Ignition Timing

|

Control zone |

Control condition |

Ignition method |

|---|---|---|

|

Engine start zone

|

Engine speed is less than 500 rpm

|

Engine starting

|

|

IR zone

|

During IR

|

IR ignition

|

|

Normal zone

|

During engine operation except for engine start zone and IR zone

|

Normal ignition (ignition timing is determined based on information from cylinder pressure sensor)

|

Ignition timing calculation method table

|

Contents

|

Calculation method or determination method for ignition timing, spark advance, and correction

|

Control zone

|

||

|

|

|||

|

Starting ignition

|

Determination based on engine coolant temperature

|

A

|

|

|

|

IR ignition

|

Determination based on engine coolant temperature

|

A

|

|

|

|

Normal ignition

|

Determination based on conditions inside cylinder (operation conditions of pressure, temperature, EGR, and each device and cylinder pressure sensor condition)

|

|

A

|

|

|

Correction

|

Engine coolant temperature spark advance correction

|

Purpose: Correction is performed because knocking and combustion period differ according to engine coolant temperature (temperature of wall inside cylinder).

|

|

B

|

|

Intake air temperature correction

|

Purpose: Correction is performed because SPCCI (Spark Controlled Compression Ignition) occurrence differs according to intake air temperature.

|

|

B

|

|

|

G/F correction (inside and outside)

|

Purpose: Correction is performed because knocking and combustion period differ according to EGR rate or fuel-air equivalence ratio.

|

|

B

|

|

|

Valve timing correction

|

Purpose: Correction is performed because combustion speed changes according to electric variable valve timing.

|

|

B

|

|

|

Swirl control valve position correction

|

Purpose: Correction is performed because combustion speed changes according to swirl control valve opening angle.

|

|

B

|

|