|

1

|

VERIFY STEERING SWITCH CONDITION

• Visually inspect each steering switch.

• Are there any switches in the steering switch that are stuck in a pressed condition?

|

Yes

|

Release the stuck switch.

• If foreign matter is caught, remove it if possible.

• The stuck switch and adjacent switch are operated any number of times.

If the stuck switch is released:

• Go to the next step.

If the stuck switch is not released

• Repair or replace the malfunctioning location and perform the repair completion verification. (Refer to the [STEERING SWITCH REMOVAL/INSTALLATION] in the workshop manual)

|

|

No

|

Go to the next step.

|

|

2

|

INSPECT STEERING SWITCH FOR MALFUNCTION

• Inspect the applicable part. (Refer to the [STEERING SWITCH INSPECTION] in the workshop manual)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

(Refer to the [STEERING SWITCH REMOVAL/INSTALLATION] in the workshop manual)

|

|

3

|

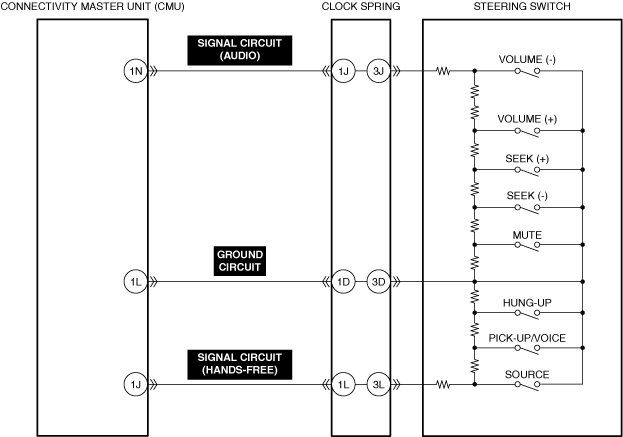

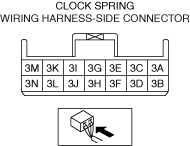

VERIFY CLOCK SPRING (AUDIO, HANDS-FREE, AND GROUND SYSTEMS) VOLTAGE

• Switch the ignition ON (engine off).

• Measure the voltage at the following terminals.

-

― Clock spring terminal 3J

― Clock spring terminal 3D

― Clock spring terminal 3L

• Are the voltage values as follows?

-

― Clock spring terminal 3J: 2.68-2.89 V

― Clock spring terminal 3D: 0 V

― Clock spring terminal 3L: 2.520-2.736 V

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 5.

|

|

4

|

INSPECT CLOCK SPRING (TERMINAL 3A—3N) CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

5

|

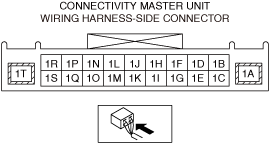

VERIFY CONNECTIVITY MASTER UNIT (CMU) (AUDIO, HANDS-FREE, AND GROUND SYSTEMS) VOLTAGE

• Switch the ignition ON (engine off).

• Measure the voltage at the following terminals.

-

― Connectivity master unit (CMU) terminal 1N

― Connectivity master unit (CMU) terminal 1L

― Connectivity master unit (CMU) terminal 1J

• Are the voltage values as follows?

-

― Connectivity master unit (CMU) terminal 1N: 2.68-2.89 V

― Connectivity master unit (CMU) terminal 1L: 0 V

― Connectivity master unit (CMU) terminal 1J: 2.520-2.736 V

|

Yes

|

Go to the next step.

|

|

No

|

Replace the connectivity master unit (CMU) and perform the repair completion verification.

(Refer to the [CONNECTIVITY MASTER UNIT (CMU) REMOVAL/INSTALLATION] in the workshop manual)

|

|

6

|

INSPECT CONNECTIVITY MASTER UNIT (CMU) CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

7

|

INSPECT CLOCK SPRING (TERMINAL 1A—1N) CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

8

|

INSPECT STEERING SWITCH SIGNAL CIRCUIT (AUDIO), SIGNAL CIRCUIT (HANDS-FREE), AND GROUND CIRCUIT FOR SHORT TO POWER SUPPLY

• Inspect the applicable circuit for a short to power supply. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

9

|

INSPECT STEERING SWITCH SIGNAL CIRCUIT (AUDIO), SIGNAL CIRCUIT (HANDS-FREE), AND GROUND CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

10

|

INSPECT STEERING SWITCH SIGNAL CIRCUITS (AUDIO), SIGNAL CIRCUITS (HANDS-FREE), AND GROUND CIRCUITS FOR SHORT CIRCUIT

• Inspect the applicable circuits for a short circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

11

|

INSPECT CLOCK SPRING FOR MALFUNCTION

• Inspect the applicable part. (Refer to the [CLOCK SPRING INSPECTION] in the workshop manual)

• Is the part normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

(Refer to the [CLOCK SPRING REMOVAL/INSTALLATION] in the workshop manual)

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory. (Refer to the [CLEARING DTC] in the workshop manual)

• Perform the DTC inspection for the connectivity master unit (CMU). (Refer to the [DTC INSPECTION] in the workshop manual)

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

(Refer to the [CONTROLLER AREA NETWORK (CAN) MALFUNCTION DIAGNOSIS FLOW] in the workshop manual)

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the connectivity master unit (CMU), then go to the next step. (Refer to the [CONNECTIVITY MASTER UNIT (CMU) REMOVAL/INSTALLATION] in the workshop manual)

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs ARE DISPLAYED

• Perform the DTC inspection. (Refer to the [DTC INSPECTION] in the workshop manual)

• Are other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|