|

1

|

VERIFY AUDIO AMPLIFIER OPERATION

• Output audio in the cabin using the audio amplifier. (Such as radio, navigation)

• Is audio output from the vehicle speakers?

|

Yes

|

Verify that the repairs have been completed.

|

|

No

|

Go to the next step.

|

|

2

|

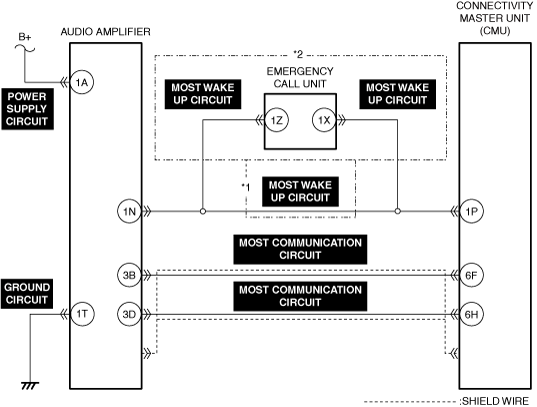

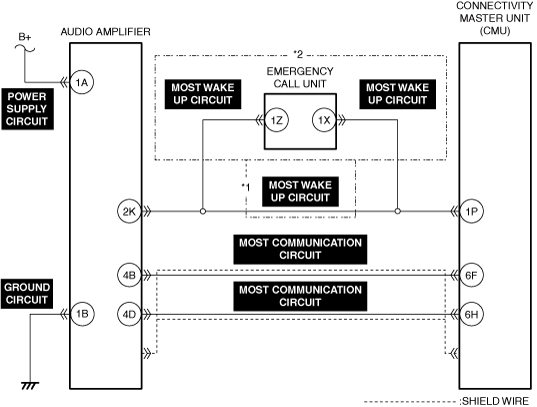

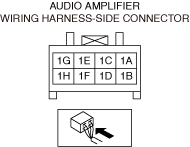

VERIFY SUPPLY VOLTAGE TO AUDIO AMPLIFIER

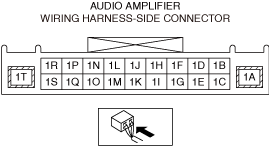

• Measure the voltage at audio amplifier terminal 1A (vehicle wiring harness side).

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

3

|

INSPECT AUDIO AMPLIFIER GROUND CIRCUIT FOR OPEN CIRCUIT

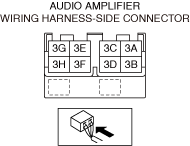

• Inspect the audio amplifier ground circuit for open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

4

|

INSPECT AUDIO AMPLIFIER CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

5

|

INSPECT AUDIO AMPLIFIER POWER SUPPLY CIRCUIT FOR SHORT TO GROUND AND OPEN CIRCUIT

• Inspect the power supply circuit for a short to ground and open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

6

|

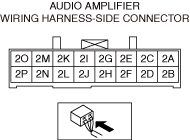

VERIFY MOST WAKE UP CIRCUIT VOLTAGE

• Measure the voltage at audio amplifier terminal 1N (vehicle wiring harness side).

• Is the voltage B+?

|

Yes

|

Go to Step 14.

|

|

No

|

Without Emergency Call System:

• Go to Step 9.

With Emergency Call System:

• Go to the next step.

|

|

7

|

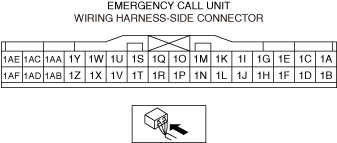

VERIFY MOST WAKE UP CIRCUIT VOLTAGE

-

Note

-

• Measure while the Emergency Call System is not operating.

• Measure the voltage at emergency call unit terminal 1Z.

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 9.

|

|

8

|

INSPECT EMERGENCY CALL UNIT FOR MALFUNCTION

• Perform the DTC inspection for the emergency call unit. (Refer to the [DTC INSPECTION] in the workshop manual))

• Is a DTC displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

(Refer to the [DTC TABLE [EMERGENCY CALL UNIT]] in the workshop manual)

|

|

No

|

Go to the next step.

|

|

9

|

INSPECT CONNECTIVITY MASTER UNIT (CMU) CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Without Emergency Call System:

• Go to Step 11.

With Emergency Call System:

• Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

10

|

INSPECT EMERGENCY CALL UNIT CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

11

|

INSPECT MOST WAKE UP CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

12

|

INSPECT MOST WAKE UP CIRCUIT FOR SHORT TO POWER SUPPLY

• Inspect the applicable circuit for a short to power supply. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

13

|

INSPECT MOST WAKE UP CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

14

|

INSPECT AUDIO AMPLIFIER CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

15

|

INSPECT CONNECTIVITY MASTER UNIT (CMU) CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

16

|

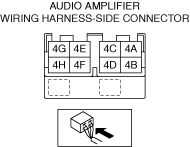

INSPECT MOST COMMUNICATION CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

17

|

INSPECT MOST COMMUNICATION CIRCUIT FOR SHORT TO POWER SUPPLY

• Inspect the applicable circuit for a short to power supply. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

18

|

INSPECT MOST COMMUNICATION CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

19

|

INSPECT FOR CONTINUITY BETWEEN MOST COMMUNICATION CIRCUIT SHIELD WIRE AND GROUND

• Inspect the applicable circuit for continuity with the body ground. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

20

|

DETERMINE MALFUNCTIONING LOCATION

• Replace the audio amplifier. (Refer to the [AUDIO AMPLIFIER REMOVAL/INSTALLATION] in the workshop manual)

• Output audio in the cabin using the audio amplifier. (Such as radio, navigation)

• Is audio output from the vehicle speakers?

|

Yes

|

Verify that the repairs have been completed.

|

|

No

|

Put back the audio amplifier that was removed, replace the connectivity master unit (CMU), and perform the repair completion verification.

(Refer to the [AUDIO AMPLIFIER REMOVAL/INSTALLATION] in the workshop manual)

(Refer to the [CONNECTIVITY MASTER UNIT (CMU) REMOVAL/INSTALLATION] in the workshop manual)

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory. (Refer to the [CLEARING DTC] in the workshop manual)

• Perform the DTC inspection for the connectivity master unit (CMU). (Refer to the [DTC INSPECTION] in the workshop manual)

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

(Refer to the [CONTROLLER AREA NETWORK (CAN) MALFUNCTION DIAGNOSIS FLOW] in the workshop manual)

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the connectivity master unit (CMU), then go to the next step. (Refer to the [CONNECTIVITY MASTER UNIT (CMU) REMOVAL/INSTALLATION] in the workshop manual)

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs ARE DISPLAYED

• Perform the DTC inspection. (Refer to the [DTC INSPECTION] in the workshop manual)

• Are other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|