|

1

|

VERIFY REPEATABILITY

• Switch the ignition ON (engine off or on).

• Clear the DTC recorded in the memory. (Refer to the [CLEARING DTC] in the workshop manual)

• Switch the ignition OFF, and then switch it ON (engine off or on) and wait for 30 s or more.

• Perform the DTC inspection for the connectivity master unit (CMU). (Refer to the [DTC INSPECTION] in the workshop manual)

• Is the same Pending DTC present?

|

Yes

|

Go to the next step.

|

|

No

|

Go to repair completion verification 2.

|

|

2

|

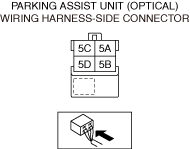

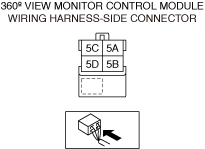

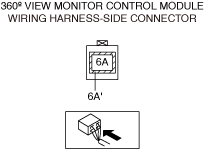

INSPECT 360°VIEW MONITOR CONTROL MODULE FOR MALFUNCTION

• Perform the DTC inspection for the vehicle control module (VCM) and 360°view monitor control module. (Refer to the [DTC INSPECTION] in the workshop manual)

• Is a DTC displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

(Refer to the [DTC TABLE [VEHICLE CONTROL MODULE]] in the workshop manual)

(Refer to the [DTC TABLE [360°VIEW MONITOR CONTROL MODULE]] in the workshop manual)

|

|

No

|

Go to the next step.

|

|

3

|

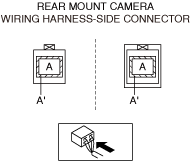

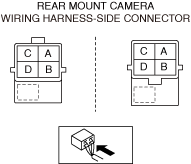

VERIFY REAR MOUNT CAMERA POWER SUPPLY CIRCUIT VOLTAGE

• Measure the voltage at rear mount camera terminal D (vehicle wiring harness side).

• Is voltage supplied?

|

Yes

|

Go to Step 9.

|

|

No

|

Go to the next step.

|

|

4

|

INSPECT REAR MOUNT CAMERA CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

5

|

INSPECT 360°VIEW MONITOR CONTROL MODULE CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

6

|

INSPECT REAR MOUNT CAMERA POWER SUPPLY CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

7

|

INSPECT REAR MOUNT CAMERA POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

8

|

INSPECT REAR MOUNT CAMERA GROUND CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to Step 11.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

9

|

INSPECT REAR MOUNT CAMERA CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

10

|

INSPECT 360°VIEW MONITOR CONTROL MODULE CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

11

|

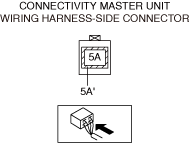

INSPECT CONNECTIVITY MASTER UNIT (CMU) CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

12

|

INSPECT REAR MOUNT CAMERA SIGNAL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

13

|

INSPECT REAR MOUNT CAMERA SIGNAL CIRCUIT FOR SHORT TO POWER SUPPLY

• Inspect the applicable circuit for a short to power supply. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

14

|

INSPECT REAR MOUNT CAMERA SIGNAL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

15

|

INSPECT FOR CONTINUITY BETWEEN REAR MOUNT CAMERA SIGNAL CIRCUIT SHIELD WIRE AND GROUND

• Inspect the applicable circuit for continuity with the body ground. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

16

|

INSPECT CONNECTIVITY MASTER UNIT (CMU) SIGNAL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

17

|

INSPECT CONNECTIVITY MASTER UNIT (CMU) SIGNAL CIRCUIT FOR SHORT TO POWER SUPPLY

• Inspect the applicable circuit for a short to power supply. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

18

|

INSPECT CONNECTIVITY MASTER UNIT (CMU) SIGNAL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

19

|

INSPECT FOR CONTINUITY BETWEEN CONNECTIVITY MASTER UNIT (CMU) SIGNAL CIRCUIT AND GROUND

• Inspect the applicable circuit for continuity with the body ground. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

20

|

DETERMINE MALFUNCTIONING LOCATION

• Clear the DTC recorded in the memory. (Refer to the [CLEARING DTC] in the workshop manual)

• Perform the DTC inspection for the connectivity master unit (CMU). (Refer to the [DTC INSPECTION] in the workshop manual)

• Are other DTCs displayed that are the same as this DTC?

|

Yes

|

Replace the connectivity master unit (CMU) and perform the repair completion verification.

(Refer to the [CONNECTIVITY MASTER UNIT (CMU) REMOVAL/INSTALLATION] in the workshop manual)

|

|

No

|

Replace the rear mount camera and perform the repair completion verification.

(Refer to the [REAR MOUNT CAMERA REMOVAL/INSTALLATION] in the workshop manual)

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory. (Refer to the [CLEARING DTC] in the workshop manual)

• Perform the DTC inspection for the connectivity master unit (CMU). (Refer to the [DTC INSPECTION] in the workshop manual)

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

(Refer to the [CONTROLLER AREA NETWORK (CAN) MALFUNCTION DIAGNOSIS FLOW] in the workshop manual)

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the connectivity master unit (CMU), then go to the next step. (Refer to the [CONNECTIVITY MASTER UNIT (CMU) REMOVAL/INSTALLATION] in the workshop manual)

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs ARE DISPLAYED

• Perform the DTC inspection. (Refer to the [DTC INSPECTION] in the workshop manual)

• Are other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|