|

1

|

VERIFY REPEATABILITY

• Switch the ignition ON (engine off or on).

• Clear the DTC recorded in the memory. (Refer to the [CLEARING DTC] in the workshop manual)

• Switch the ignition OFF, and then switch it ON (engine off or on) and wait for 30 s or more.

• Perform the DTC inspection for the connectivity master unit (CMU). (Refer to the [DTC INSPECTION] in the workshop manual)

• Is the same Pending DTC present?

|

Yes

|

Perform the DTC inspection for the emergency call unit.

(Refer to the [DTC INSPECTION] in the workshop manual)

If DTC is displayed

• Repair the malfunctioning location according to the applicable DTC troubleshooting. (Refer to the [DTC TABLE [EMERGENCY CALL UNIT]] in the workshop manual)

If DTC is not displayed

• Go to the next step.

|

|

No

|

Go to repair completion verification 2.

|

|

2

|

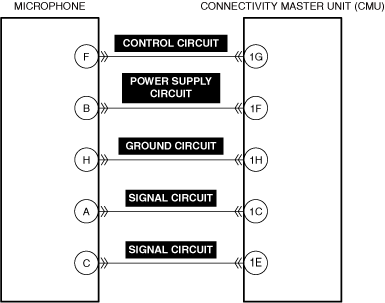

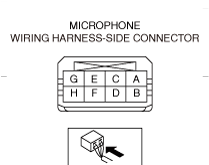

VERIFY VOLTAGE SUPPLIED TO MICROPHONE

• Measure the voltage at microphone terminal B (vehicle wiring harness side).

• Is the voltage approx. 8.0 V?

|

Yes

|

Go to Step 9.

|

|

No

|

Go to the next step.

|

|

3

|

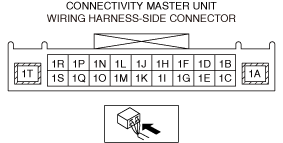

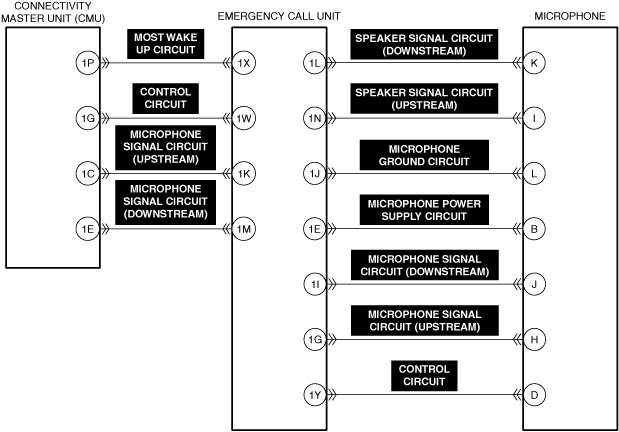

VERIFY VOLTAGE WHICH EMERGENCY CALL UNIT IS SUPPLYING

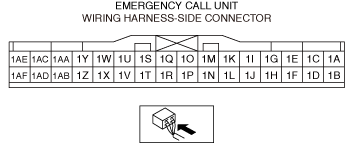

• Measure the voltage at emergency call unit 1E.

• Is the voltage approx. 8.0 V?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the emergency call unit and perform the repair completion verification.

(Refer to the [EMERGENCY CALL UNIT REMOVAL/INSTALLATION] in the workshop manual)

|

|

4

|

INSPECT MICROPHONE CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

5

|

INSPECT EMERGENCY CALL UNIT CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

6

|

INSPECT MICROPHONE POWER SUPPLY CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

7

|

INSPECT MICROPHONE POWER SUPPLY CIRCUIT FOR SHORT TO POWER SUPPLY

• Inspect the applicable circuit for a short to power supply. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

8

|

INSPECT MICROPHONE POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

9

|

INSPECT MICROPHONE CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

10

|

INSPECT EMERGENCY CALL UNIT CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

11

|

INSPECT MICROPHONE GROUND CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

12

|

VERIFY VOLTAGE SUPPLIED FROM MICROPHONE CONTROL CIRCUIT

• Measure the voltage at microphone terminal D (vehicle wiring harness side).

• Is the voltage approx. 8.0 V?

|

Yes

|

Replace the microphone and perform the repair completion verification

(Refer to the [MICROPHONE REMOVAL/INSTALLATION] in the workshop manual)

|

|

No

|

Go to the next step.

|

|

13

|

VERIFY VOLTAGE SUPPLIED AT CONTROL CIRCUIT CONTROLLED BY EMERGENCY CALL UNIT

• Measure the voltage at emergency call unit terminal 1Y.

• Is the voltage approx. 8.0 V?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the emergency call unit and perform the repair completion verification.

(Refer to the [EMERGENCY CALL UNIT REMOVAL/INSTALLATION] in the workshop manual)

|

|

14

|

INSPECT MICROPHONE CONTROL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

15

|

INSPECT MICROPHONE CONTROL CIRCUIT FOR SHORT TO POWER SUPPLY

• Inspect the applicable circuit for a short to power supply. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

16

|

INSPECT MICROPHONE CONTROL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

17

|

VERIFY VOLTAGE SUPPLIED FROM EMERGENCY CALL UNIT CONTROL CIRCUIT

• Measure the voltage at emergency call unit terminal 1W (vehicle wiring harness side).

• Is the voltage approx. 5.43 V?

|

Yes

|

Replace the emergency call unit and perform the repair completion verification.

(Refer to the [EMERGENCY CALL UNIT REMOVAL/INSTALLATION] in the workshop manual)

|

|

No

|

Go to the next step.

|

|

18

|

VERIFY VOLTAGE SUPPLIED AT CONTROL CIRCUIT CONTROLLED BY CONNECTIVITY MASTER UNIT (CMU)

• Measure the voltage at connectivity master unit (CMU) terminal 1G.

• Is the voltage approx. 5.43 V?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the connectivity master unit (CMU) and perform the repair completion verification.

(Refer to the [CONNECTIVITY MASTER UNIT (CMU) REMOVAL/INSTALLATION] in the workshop manual)

|

|

19

|

INSPECT CONNECTIVITY MASTER UNIT (CMU) CONNECTOR FOR MALFUNCTION

• Inspect the applicable connector and terminal. (Refer to the [CONNECTOR INSPECTION] in the workshop manual)

• Are the connector and terminal normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

20

|

INSPECT EMERGENCY CALL UNIT CONTROL CIRCUIT FOR SHORT TO GROUND

• Inspect the applicable circuit for a short to ground. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

21

|

INSPECT EMERGENCY CALL UNIT CONTROL CIRCUIT FOR SHORT TO POWER SUPPLY

• Inspect the applicable circuit for a short to power supply. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

22

|

INSPECT EMERGENCY CALL UNIT CONTROL CIRCUIT FOR OPEN CIRCUIT

• Inspect the applicable circuit for an open circuit. (Refer to the [CIRCUIT INSPECTION] in the workshop manual)

• Is the circuit normal?

|

Yes

|

Replace the emergency call unit and perform the repair completion verification.

(Refer to the [EMERGENCY CALL UNIT REMOVAL/INSTALLATION] in the workshop manual)

|

|

No

|

Repair or replace the malfunctioning location and perform the repair completion verification.

|

|

Repair completion verification 1

|

VERIFY THAT VEHICLE IS REPAIRED

• Install/connect the part removed/disconnected during the troubleshooting procedure.

• Clear the DTC recorded in the memory. (Refer to the [CLEARING DTC] in the workshop manual)

• Perform the DTC inspection for the connectivity master unit (CMU). (Refer to the [DTC INSPECTION] in the workshop manual)

• Is the same Pending DTC present?

|

Yes

|

Refer to the controller area network (CAN) malfunction diagnosis flow to inspect for a CAN communication error.

(Refer to the [CONTROLLER AREA NETWORK (CAN) MALFUNCTION DIAGNOSIS FLOW] in the workshop manual)

If the CAN communication is normal, perform the diagnosis from Step 1.

• If the malfunction recurs, replace the connectivity master unit (CMU), then go to the next step. (Refer to the [CONNECTIVITY MASTER UNIT (CMU) REMOVAL/INSTALLATION] in the workshop manual)

|

|

No

|

Go to the next step.

|

|

Repair completion verification 2

|

VERIFY IF OTHER DTCs ARE DISPLAYED

• Perform the DTC inspection. (Refer to the [DTC INSPECTION] in the workshop manual)

• Are other DTCs displayed?

|

Yes

|

Repair the malfunctioning location according to the applicable DTC troubleshooting.

|

|

No

|

DTC troubleshooting completed.

|