|

b3e0110e083

CRANKSHAFT INSPECTION

id011000502500

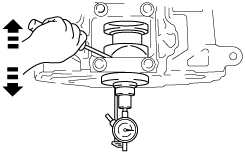

1. Measure the crankshaft end play using a dial gauge.

b3e0110e083

|

2. Measure the runout of the main journal using a V-block and dial gauge.

beltze00000001

|

3. Inspect the main journal diameter and crank pin diameter. Measurement positions total four and are in the X and Y directions, at two points (A and B) as shown in the figure.

b3e0110e085

|

4. Inspect the main journal oil clearance using the following procedure.

beltze00000002

|

b3e0110e086

|