|

ON-BOARD DIAGNOSTIC TEST [MZR-CD 2.2]

id0102f3801000

DTC Reading Procedure

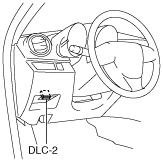

1. Connect the M-MDS to the DLC‐2.

am3zzw00005280

|

2. After the vehicle is identified, select the following items from the initialization screen of the M-MDS.

3. Then, select the “Retrieve CMDTCs” and perform procedures according to directions on the M-MDS screen.

4. Verify the DTC according to the directions on the M-MDS screen.

5. After completion of repairs, clear all DTCs stored in the PCM, while referring to “AFTER REPAIR PROCEDURE“.

Pending Trouble Code Access Procedure

1. Connect the M-MDS to the DLC‐2.

am3zzw00005280

|

2. After the vehicle is identified, select the following items from the initialization screen of the M-MDS.

3. Then, select the “Retrieve CMDTCs” and perform procedures according to directions on the M-MDS screen.

4. Retrieve the pending trouble codes according to the directions on the M-MDS screen.

Freeze Frame PID Data Access Procedure

1. Connect the M-MDS to the DLC‐2.

am3zzw00005280

|

2. After the vehicle is identified, select the following items from the initialization screen of the M-MDS.

3. Then, select the “Retrieve CMDTCs” and perform procedures according to directions on the M-MDS screen.

4. Retrieve the freeze frame PID data according to the directions on the M-MDS screen.

Freeze frame data table

|

Freeze frame data item |

Unit |

Description |

Corresponding PID data monitor item |

|---|---|---|---|

|

LOAD

|

%

|

Ratio of current intake air amount to wide open throttle engine operation intake air amount

|

LOAD

|

|

ECT

|

°C

|

Engine coolant temperature

|

ECT

|

|

MAP

|

Kpa

|

Manifold absolute pressure

|

MAP

|

|

RPM

|

RPM

|

Engine speed

|

RPM

|

|

VSS

|

KPH

|

Vehicle speed input from ABS/DSC HU/CM

|

VSS

|

|

BAT

|

°C

|

Intake air temperature after super charged

|

BAT

|

|

MAF

|

g/Sec

|

Mass airflow of intake-air

|

MAF

|

|

TP

|

%

|

Intake shutter valve position

|

ISV_POS

|

|

FRP

|

Kpa

|

Fuel pressure at common rail

|

FRP

|

|

EQ_RAT11

|

—

|

Ratio of consumed air amount based on engine operation and theoretical air amount

|

—

|

|

O2S11

|

V

|

A/F sensor output voltage

|

—

|

|

WARMUPS

|

—

|

Number of warm-up cycles after all stored DTCs cleared

|

—

|

|

CLR_DIST

|

km

|

Mileage after all stored DTCs cleared

|

—

|

|

BARO

|

Kpa

|

Barometric pressure

|

BARO

|

|

EQ_RAT11

|

—

|

Ratio of consumed air amount based on engine operation and theoretical air amount

|

EQ_RAT11

|

|

O2S11

|

A

|

A/F sensor output current

|

O2S11

|

|

CATTEMP11

|

°C

|

Exhaust gas temperature sensor No.1 value

|

EXHTEMP1

|

|

CATTEMP21

|

°C

|

Exhaust gas temperature sensor No.2 value

|

EXHTEMP2

|

|

VPWR

|

V

|

PCM power supply voltage

|

VPWR

|

|

AAT

|

°C

|

Intake air temperature

|

IAT

|

|

APP_D

|

%

|

APP sensor No.1 value

|

APP1

|

|

APP_E

|

%

|

APP sensor No.2 value

|

APP2

|

|

TAC_PCT

|

%

|

Target intake shutter valve opening angle calculated from engine operating conditions

|

ISV_DSD

|

Snapshot data table

|

Snapshot data item |

Unit |

Description |

Corresponding PID data monitor item |

|---|---|---|---|

|

LOAD

|

%

|

Ratio of current intake air amount to wide open throttle engine operation intake air amount

|

LOAD

|

|

ECT

|

°C

|

Engine coolant temperature

|

ECT

|

|

MAP

|

Pa

|

Manifold absolute pressure

|

MAP

|

|

RPM

|

RPM

|

Engine speed

|

RPM

|

|

VSS

|

KPH

|

Vehicle speed input from ABS/DSC HU/CM

|

VSS

|

|

BAT

|

°C

|

Intake air temperature after super charged

|

BAT

|

|

MAF

|

g/sec

|

Mass airflow of intake-air

|

MAF

|

|

ISV_POS

|

%

|

Intake shutter valve position

|

ISV_POS

|

|

FRP

|

Pa

|

Fuel pressure at common rail

|

FRP

|

|

O2S11

|

V

|

A/F sensor output voltage

|

—

|

|

A

|

A/F sensor output current

|

O2S11

|

|

|

CLR_CNT

|

—

|

Number of warm-up cycles after all stored DTCs cleared

|

—

|

|

CLR_DIST

|

Km

|

Mileage after all stored DTCs cleared

|

—

|

|

BARO

|

Pa

|

Barometric pressure

|

BARO

|

|

EQ_RAT11

|

—

|

Ratio of consumed air amount based on engine operation and theoretical air amount

|

EQ_RAT11

|

|

EXHTEMP1

|

°C

|

Exhaust gas temperature sensor No.1 value

|

EXHTEMP1

|

|

EXHTEMP2

|

°C

|

Exhaust gas temperature sensor No.2 value

|

EXHTEMP2

|

|

EXHTEMP3

|

°C

|

Exhaust gas temperature sensor No.3 value

|

EXHTEMP3

|

|

VPWR

|

V

|

PCM power supply voltage

|

VPWR

|

|

IAT

|

°C

|

Intake air temperature

|

IAT

|

|

APP1

|

%

|

APP sensor No.1 value

|

APP1

|

|

APP2

|

%

|

APP sensor No.2 value

|

APP2

|

|

ISV_DSD

|

%

|

Target intake shutter valve opening angle calculated from engine operating conditions

|

ISV_DSD

|

PID/DATA Monitor And Record Procedure

1. Connect the M-MDS to the DLC‐2.

am3zzw00005280

|

2. After the vehicle is identified, select the following items from the initialization screen of the M-MDS.

3. Select the PID from the PID table.

4. Verify the PID data according to the directions on the M-MDS screen.

Active Command Modes Procedure

1. Connect the M-MDS to the DLC‐2.

am3zzw00005280

|

2. After the vehicle is identified, select the following items from the initialization screen of the M-MDS.

3. Select the simulation items from the PID table.

4. Perform the simulation function, inspect the operations for each parts.