TURBOCHARGER INSPECTION [L3 Turbo]

id0113b5801000

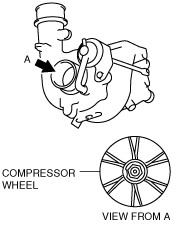

Compressor Wheel Inspection

1. Remove the turbocharger. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [L3 Turbo].)

2. Visually inspect the compressor wheel from view A for the cracks, damage, or bending on all the compressor wheel blades.

-

• If there are any cracks or damage, replace the turbocharger. (See

INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [L3 Turbo].)

-

Note

-

• If there is contact between the compressor wheel and compressor housing, there may be cracks, damage, or bending on the blade end area.

• If there are cracks, damage, or bending on the compressor wheel, verify the following after replacing the turbocharger.

-

― Intake air/exhaust system related components

― Oil outlet pipe and oil inlet pipe damage

Turbine wheel inspection

1. Remove the turbocharger. (See INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [L3 Turbo].)

2. Visually inspect the turbine wheel from view B for the cracks, damage, or bending on all the turbine wheel blades.

-

• If there are cracks, damage, or bending on the turbine wheel, replace the turbocharger. (See

INTAKE-AIR SYSTEM REMOVAL/INSTALLATION [L3 Turbo].)

-

Note

-

• If there is contact between the turbine wheel and turbine housing, there may be cracks, damage, or bending on the blade end area.

• If there are cracks, damage, or bending on the turbine wheel, verify the following after replacing the turbocharger.

-

― Intake air/exhaust system related components

― Oil outlet pipe and oil inlet pipe damage