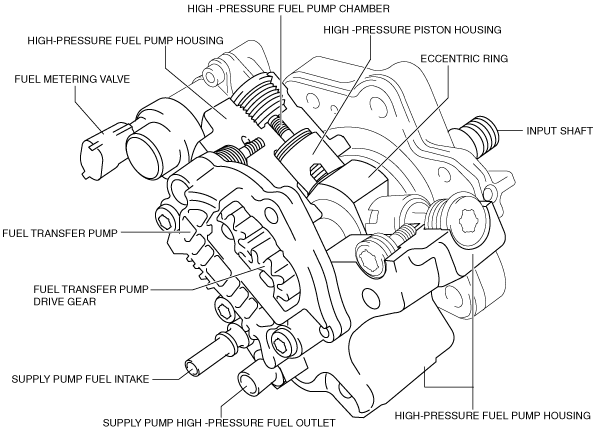

• The high-pressure fuel pump is driven by the timing belt through the input shaft. The input shaft rotates an eccentric lobe within the eccentric ring. The eccentric ring is forced against the high-pressure pistons to produce the high pressure fuel supply.

• During each revolution of the input shaft, all three high-pressure fuel pump chambers will deliver pressurized fuel to the common rail.

• During the high-pressure fuel development stage, fuel in the high-pressure fuel pump chamber is compressed by the high-pressure piston until the pressure in the fuel pump high-pressure chamber exceeds the fuel pressure in the common rail. At this point the high-pressure fuel outlet valve opens and allows fuel to be delivered to the common rail. As the high-pressure piston reaches the end of its compression stroke, the fuel pressure in the common rail and the fuel pump chamber equalize.

• As the eccentric ring rotates, the high-pressure piston will retract from the high-pressure chamber under the force of the high-pressure piston return spring. The fuel pressure in the common rail will become greater than the fuel pressure in the high-pressure chamber. This will make the high-pressure fuel outlet valve close, so maintaining the fuel pressure in the common rail.

• When the fuel pressure in the high-pressure chamber drops below the fuel pressure developed by the fuel transfer pump, the high-pressure chamber fuel intake valve will open and allow fuel to be delivered from the fuel transfer pump to the high-pressure chamber. The fuel transfer pump will continue to deliver fuel to the high-pressure chamber until the high-pressure fuel development stage has started and the developing fuel pressure in the high-pressure chamber exceeds the fuel pressure of the transfer pump at which point the high-pressure chamber fuel intake valve will close.