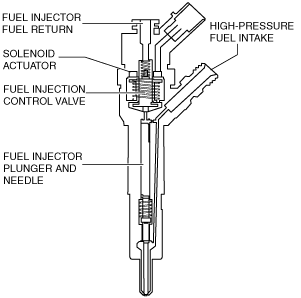

FUEL INJECTOR CONSTRUCTION [MZ-CD 1.6 (Y6)]

id0114c3152000

EURO4 Emission Level

• Individual fuel injectors are measured for flow characteristics and assigned a calibration code which is printed on the head of the fuel injector. The calibration code is used by the PCM to adjust the fuel injector injection signal to achieve optimum efficiency. The fuel injectors are designed to allow a quantity of fuel to return to the fuel system. The returned fuel is developed during the opening cycle of the fuel injector control valve. This returned fuel is used to lubricate the fuel injector moving components and is essential to the operation of the fuel injector. This lubricating fuel is returned to the fuel tank through the fuel injector fuel return line. Only by accurate measurement, at precise engine conditions, can the volumes of fuel from the fuel injector fuel return be used to diagnose concerns with the fuel charging control system.

EURO5 Emission Level

-

Caution

-

• The wiring harness connectors must never be disconnected from the piezo fuel injectors while the engine is running. If the current is cut during the charging phase, the piezo actuators remain extended for a certain time so that the nozzles are still open. This results in continuous injection and engine damage.

• The start of injection and the injection quantity specified by the PCM are implemented by means of the piezo-fuel injectors.

• Extremely short switching times of approximately 150 µs permit extremely rapid reactions to changes in the operating conditions. The fuel quantity to be injected can thus be metered very precisely.

• The fuel injectors are divided into three assemblies:

-

― Injector head, containing among other things the piezo actuator

― Hydraulic circuit

― Fuel injector nozzle

• When servicing, the seal which seals the combustion chamber must be replaced.