VARIABLE VALVE TIMING CONTROL OPERATION [MZR 2.0 DISI i-stop]

id0140j1171300

• The PCM divides the OCV drive range into four modes according to engine operation conditions. The OCV drive current is determined based on the target current calculated in each mode.

Cleaning Mode

Mode execution condition

-

• When the following condition is met:

-

― Fully-closed throttle valve during deceleration

― Engine speed is 2,250—3,500 rpm

― Engine coolant temperature is above 80 °C {176 °F}

Purpose

-

• Cleaning mode is to remove foreign material in the OCV hydraulic passages.

Maximum Cam Retard Mode

Mode execution condition

-

• When any of the following conditions are met:

-

― Idling

― Engine coolant temperature is less than 20 °C {68 °F}

― Engine speed is less then 968 rpm

― When the fuel injection control is in the start zone

Purpose

-

• Maximum cam retard mode stabilizes engine speed by maximally retarding the valve timing when the engine speed is low during idling.

Feedback Hold Mode

Mode execution condition

-

• Target valve timing and actual valve timing are almost the same.

Purpose

-

• The feedback hold mode holds the valve timing by returning the OCV spool valve to the neutral position when target valve timing suitable for the engine operation conditions is obtained.

Feedback Mode

Mode execution condition

-

• Except during cleaning, maximum cam retard, or feedback hold modes.

Purpose

-

• Feedback mode obtains valve timing suitable for engine operation conditions by performing the feedback operation so that present OCV drive current is set closer to the target current determined by the PCM according to engine operation conditions.

Advance speed correction

• If there is a large difference between the target valve timing and the actual valve timing, the target current correction is applied so that it is set closer to the target valve timing more quickly to raise the advance speed by advancing the spool valve initialization operation.

• The variable valve timing actuator advance speed increases as the hydraulic passage in the OCV widens and decreases as it narrows.

Valve timing determination

• The PCM controls current to the OCV to obtain optimum valve timing suitable for the engine operation conditions (target valve timing).

• The PCM compares target valve timing with actual valve timing, and feeds back the result to change valve timing smoothly.

Target valve timing

-

• Determined according to engine speed, engine coolant temperature and charging efficiency.

Actual valve timing

-

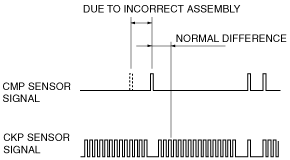

• Means present valve timing. Actual valve timing is calculated by adding the maximum cam retard learning value for energization from the value detected by the CMP and CKP sensors.

Cam maximum retard learning value

-

• Though the intake camshaft valve timing (including maximum retard position) is detected based on the difference between the signal from the sensor and signal from the CKP sensor, the difference between the signals deviates due to the sensor installation condition. Because of this, the PCM stores the difference between the signal build-ups at the maximum OCV retard position to prevent deviation in valve timing detection.