|

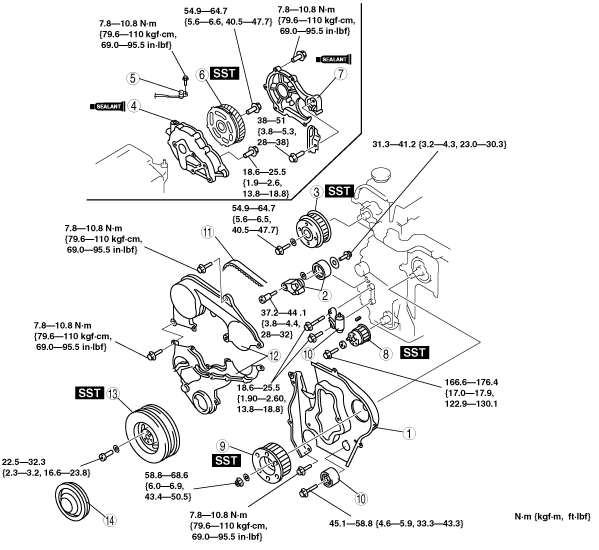

TIMING BELT ASSEMBLY [WITH DIESEL PARTICULATE FILTER]

id0110f3504500

1. Assemble in the order indicated in the table.

gpe110ze1052

|

|

1

|

Seal plate

(See Seal Plate Assembly Note)

|

|

2

|

Tensioner

|

|

3

|

Camshaft pulley

|

|

4

|

Gear case

(See Gear Case Assembly Note)

|

|

5

|

Camshaft position sensor

|

|

6

|

Drive gear

(See Drive Gear Assembly Note)

|

|

7

|

Gear cover

(See Gear Cover Assembly Note)

|

|

8

|

Timing belt pulley

|

|

9

|

Supply pump pulley

|

|

10

|

Idler (See Idler Assembly Note)

|

|

11

|

Timing belt, timing belt auto tensioner

|

|

12

|

Timing belt cover

|

|

13

|

Crankshaft pulley

|

|

14

|

Pulley cover

|

Seal Plate Assembly Note

1. Install the seal plate and hand tighten the bolts in the order A to B.

2. Tighten the bolts in the order shown.

bej0110e071

|

Camshaft Pulley Assembly Note

1. Hold the camshaft using the SST.

bej0110e009

|

Gear Case Assembly Note

1. Apply silicone sealant as shown in the figure.

ame2524e011

|

2. Tighten the bolts in clockwise order.

Drive Gear Assembly Note

1. Hold the camshaft using the SST.

2. Remove the drive gear lock bolt.

dpe110ze1038

|

Gear Cover Assembly Note

1. Apply silicone sealant as shown in the figure.

dpe110ze1043

|

2. Tighten the bolts in clockwise order.

Timing Belt Pulley Assembly Note

1. Hold the crankshaft using the SST.

2. Tighten the timing belt pulley lock bolt.

dpe110ze1059

|

Supply Pump Pulley Assembly Note

1. Hold the supply pump pulley using the SST and Install the supply pump pulley lock nut.

am6zzw00003642

|

Idler Assembly Note

dpe110ze1030

|

Timing Belt, Timing Belt Auto Tensioner Assembly Note

1. Verify the thrust of the auto tensioner rod in the following order:

dpe110ze1047

|

2. Verify that all timing marks are correctly aligned.

3. Fix the camshaft pulley to the cylinder head using bolt (M8 x 1.25).

4. Lock the supply pump pulley against rotation using the FIP repair kit.

dpe110ze1057

|

5. If not, align all timing marks according to the following procedure.

6. Install the timing belt on the pulleys in the following order.

dpe110bw1017

|

7. Remove the supply pump pulley fixing bolts and camshaft pulley fixing bolt (M8 x 1.25).

8. Hand–tighten the auto tensioner bolts in the order A to B.

9. Tighten the auto tensioner bolts in the order A to B.

bej0110e075

|

10. Remove the pin from the auto tensioner to apply tension to the belt.

11. Turn the crankshaft clockwise twice, and align the timing marks.

12. Verify that all timing marks are correctly aligned. If not, repeat from Timing Belt, Timing Belt Auto Tensioner Removal Note.

Crankshaft Pulley Assembly Note

1. Hold the crankshaft using the SST.

dpe110ze1059

|

2. Tighten the bolts in the order shown.

dpe110ze1042

|