|

adj2224e023

TAPPET INSPECTION

id011000505800

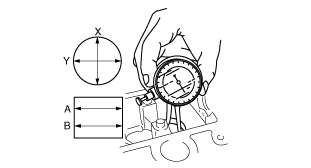

1. Measure the diameter of each tappet bore using the caliper gauge. Measurement positions total four and are in the X and Y directions, at two points (A and B) as shown in the figure.

adj2224e023

|

2. Measure the tappet body outer diameter of each valve using the micrometer. Measurement positions total four and are in the X and Y directions, at two points (A and B) as shown in the figure.

adj2224e029

|

3. Calculate the clearance between the tappet and the related tappet bore by subtracting the outer diameter of the tappet from the inner diameter of the tappet bore.