|

am3zzn00001471

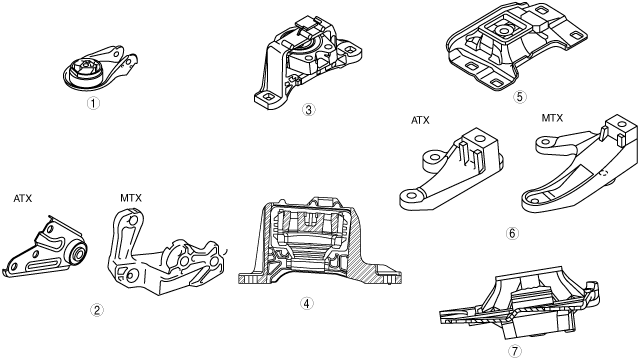

ENGINE MOUNT CONSTRUCTION[LF, L3]

id0110a0102600

am3zzn00001471

|

|

1

|

No.1 engine mount rubber

|

|

2

|

No.1 engine mount bracket

|

|

3

|

No.3 engine mount rubber

|

|

4

|

No.3 engine mount rubber sectional view

|

|

5

|

No.4 engine mount rubber

|

|

6

|

No.4 engine mount bracket

|

|

7

|

No.4 engine mount rubber sectional view

|

am3zzn00001472

|

|

1

|

Powertrain system upper surface

|

|

2

|

No.3 engine mount

|

|

3

|

Engine

|

|

4

|

Vehicle front

|

|

5

|

Vehicle rear

|

|

6

|

No.1 engine mount

|

|

7

|

Transaxle

|

|

8

|

No.4 engine mount

|

|

9

|

Powertrain system back

|

|

10

|

Engine front

|

|

11

|

Torque

|

|

12

|

Engine back

|