|

am3zzn00001303

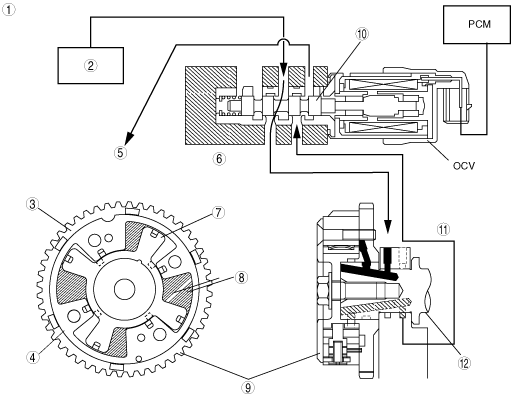

VARIABLE VALVE TIMING MECHANISM CONSTRUCTION/OPERATION[L3 Turbo]

id0110b3102000

Component and Function

|

Variable valve timing actuator

|

• Continuously modifies the phases of the intake camshaft and crankshaft at the forward end of the intake camshaft using hydraulic pressure from the oil control valve (OCV).

|

|

OCV

|

• Operated by current (duty signal) from the PCM. Switches the hydraulic oil passages to the variable valve timing actuator.

|

|

CKP sensor

|

• Input the engine revolution signal to the PCM.

|

|

CMP sensor

|

• Inputs the cylinder identification signal to the PCM.

|

|

PCM

|

• Controls the OCV so that optimum valve timing is obtained according to engine operation conditions.

|

Operation outline

am3zzn00001303

|

|

1

|

Hydraulic pressure flow

|

|

2

|

Oil pump

|

|

3

|

Housing

|

|

4

|

Case

|

|

5

|

Oil pan

|

|

6

|

To valve timing advance chamber

|

|

7

|

Rotor

|

|

8

|

Valve timing advance chamber

|

|

9

|

Variable valve timing actuator

|

|

10

|

Spool valve

|

|

11

|

From valve timing retard chamber

|

|

12

|

Camshaft

|

am3zzn00001304

|

|

1

|

Hydraulic pressure flow

|

|

2

|

Oil pump

|

|

3

|

Oil pan

|

|

4

|

Housing

|

|

5

|

Case

|

|

6

|

From valve timing advance chamber

|

|

7

|

Valve timing retard chamber

|

|

8

|

Rotor

|

|

9

|

Variable valve timing actuator

|

|

10

|

Spool valve

|

|

11

|

To valve timing retard chamber

|

|

12

|

Camshaft

|

am3zzn00001305

|

|

1

|

Oil pump

|

|

2

|

To valve timing advance chamber

|

|

3

|

To valve timing retard chamber

|