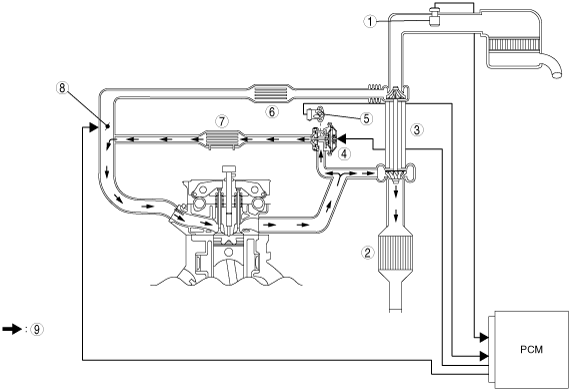

EGR SYSTEM OUTLINE[MZ-CD 1.6 (Y6)]

id0116c3100500

• By using turbochargers, the temperatures in the combustion chamber rise together with the compression and combustion performance.

• In addition, the combustion temperatures are increased by using the direct fuel injection method.

• Both measures increase the formation of nitrogen oxides (NOx) in the exhaust gas. In order to keep this NOx content in the exhaust gas within required limits, the EGR system is becoming increasingly important.

• In the part load range, exhaust gas recirculation is achieved by mixing the exhaust gases with the intake air. This reduces the oxygen concentration in the intake air. In addition, exhaust gas has a higher specific heat capacity than air and the proportion of water in the recirculated exhaust gas also reduces the combustion temperatures.

• These effects lower the combustion temperatures (and thereby the proportion of NOx) and also reduce the amount of exhaust gas emitted. The quantity of exhaust gas to be recirculated is accurately determined by the PCM. An excessive exhaust gas recirculation rate would lead to an increase in diesel particulate, CO and HC emissions due to lack of air.

• For this reason, the PCM requires feedback on the recirculated amount of exhaust gases. This works via the MAF sensor and a position sensor which is integrated into the servo motor unit of the EGR valve.

• The servo motor itself is activated by the PCM depending on requirements.

|

1

|

MAF sensor

|

|

2

|

Oxidation catalytic converter

|

|

3

|

Turbocharger

|

|

4

|

EGR valve servo motor

|

|

5

|

EGR valve position sensor

|

|

6

|

Charge air cooler

|

|

7

|

EGR water cooler

|

|

8

|

Intake throttle valve

|

|

9

|

Exhaust gas flow

|