DIESEL PARTICULATE FILTER SYSTEM OUTLINE[MZ-CD 1.6 (Y6)]

id0116c3151300

High Power-Euro 4

• Diesel particulates are a complex mixture of solids and liquid components and their composition changes. diesel particulate filter systems have proved to be an effective means of reducing particulate emissions.

• The challenge, however, lies not in the filtration of the particulates, but in the regeneration of the systems. Regeneration is the burning of deposited particulates (soot volume) in the diesel particulate filter, which have collected there during the period of operation.

• To reduce the soot ignition temperature and to accelerate the burning of the soot, a fuel additive based on cerium and iron is used; this is carried in a fuel additive tank and a metered quantity of the fuel additive is injected into the fuel tank each time the fuel tank is filled with fuel. The fuel additive mixture is then injected into the combustion chamber through the injectors.

• The formation of ash from the oxidation of the fuel additive during combustion and the build-up of ash residues from the engine oil and fuel cause deposits to form which increase the exhaust gas back pressure of the diesel particulate filter over the period of operation. These ash residues cannot be converted any further and remain in the diesel particulate filter. For these reasons, the diesel particulate filter must be maintained in accordance with maintenance instructions.

Regeneration of the Diesel Particulate Filter

-

Note

-

• Soot particles can accumulate in the exhaust tailpipe. This is an inherent by-product of the regeneration process and should not be considered a concern.

• During regeneration it is possible that white smoke may be emitted from the exhaust tailpipe. This is an inherent by-product of the regeneration process and should not be considered a concern.

-

• The diesel particulate filter differential pressure sensor is connected to the diesel particulate filter by the diesel particulate filter differential sensor lines to monitor the pre-pressure and post-pressure of the diesel particulate filter. The diesel particulate filter differential pressure sensor converts these measurements to a signal voltage, which is then sent to the PCM to be used as part of the determination as to whether to apply the regeneration process or not.

• The PCM will choose the optimum time for the regeneration of the diesel particulate filter. Under normal operating conditions the regeneration process occurs when the PCM has calculated that the diesel particulate filter requires regeneration and that predetermined vehicle conditions are met (for example, coolant temperature, vehicle speed and engine load).

• The engine management system will then close the exhaust gas recirculation (EGR) valve and actuate the turbocharger. This will then generate more engine load and the exhaust gas velocity is reduced. Then, with the aid of the fuel additive and post injection, the soot particles are burnt.

• Following regeneration there is an ash residue left in the diesel particulate filter. Due to this ash residue in the diesel particulate filter must be serviced every 120,000 km {74564.5 mile}.

Manual regeneration of the Diesel Particulate Filter

-

• If the diesel particulate filter becomes blocked the diesel particulate filter differential pressure sensor will register a high pressure DTC with the PCM, the MIL will be illuminated and the limp-home mode activated.

• A blocked diesel particulate filter can be a result of:

-

― Excessive soot particles production

― Multiple failed regeneration events

― Mechanical or electrical failure of a related system or sub-system (for example, EGR valve stuck open, charge air system leak, fuel injectors)

• A static manual regeneration or drive cycle manual regeneration of the diesel particulate filter can be used to clear the soot particles from the diesel particulate filter.

|

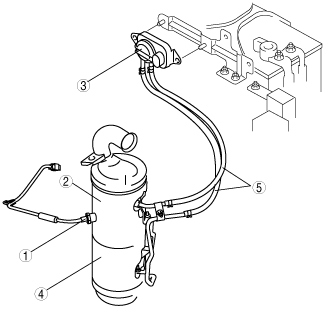

1

|

Catalyst exhaust gas temperature sensor

|

|

2

|

Catalytic converter

|

|

3

|

Diesel particulate filter differential pressure sensor

|

|

4

|

Diesel particulate filter

|

|

5

|

Diesel particulate filter differential pressure sensor lines

|