CRANKSHAFT POSITION (CKP) SENSOR CONSTRUCTION/OPERATION[LF, L3]

id0140a9104800

|

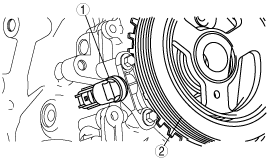

1

|

CKP sensor

|

|

2

|

Crankshaft pulley

|

• Installed on the side surface of the cylinder block (driver’s side).

• The crankshaft position sensor pulse wheel has 30 projections and spaces with 10 ° of crank angle between each projection.

• The fluctuation in magnetic flux density detected by the magnetic pickup coil in the crankshaft position sensor is input to the PCM as voltage.

• The projections on the plate installed to the crankshaft pulley cause a change in the magnetic flux when they pass near the magnetic sensor of the CKP sensor by the rotation of the crankshaft. The CKP sensor converts the change in magnetic flux to a digital waveform (rectangular waves) by the processing circuit. The PCM detects the engine speed and crankshaft position based on the crankshaft position waveforms.

|

1

|

Rotation

|

|

2

|

CKP sensor

|

|

3

|

Empty space

|

|

4

|

Pulse wheel

|

|

5

|

Main relay

|

|

6

|

CKP output signal

|