MULTIPLE FUEL INJECTION CONTROL OPERATION [MZR-CD (RF Turbo)]

id0140f1738500

Function

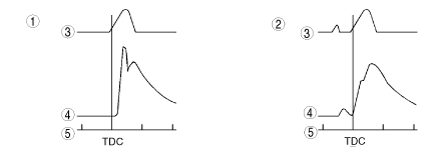

• In single injection, ignition delay becomes longer and much fuel is injected before ignition since the ignition has started. Therefore, the fuel is combusted rapidly at a high temperature and a high pressure, resulting in increased noise and NOx.

• To prevent this, the PCM performs multiple fuel injection. Due to this, the fuel is combusted slowly and the occurrence of noise and NOx is suppressed.

|

1

|

Single injection

|

|

2

|

Multiple injection

|

|

3

|

Injection pattern

|

|

4

|

Fuel injection delay

|

|

5

|

Crank angle

|

Operation

• Injection patterns of the multistage injection control according to the combination of injection times are shown in the figure. The PCM selects the optimum injection pattern based on the vehicle conditions and performs injection for 5 times at maximum.

• While in a driving condition at low engine speed and low engine load, the fuel injection time is increased up to 4 times to reduce knocking noise which occurs during combustion.

• While in a driving condition at high engine speed and high engine load, the fuel injection time is reduced to one time at minimum to improve output and fuel economy.

• During diesel particulate filter regeneration, fuel injection is performed at a slower timing to burn and remove the particulate matter accumulated in the diesel particulate filter.

First, after the main injection, the follow-up injection is performed to increase the exhaust pipe temperature.

Then, post injection is performed twice to increase the exhaust gas temperature necessary for diesel particulate filter regeneration. When the unburned fuel (HC) generated by the post injections reaches the oxidation catalytic converter, it is activated at the catalyst, and the exhaust gas temperature is increased. Because fuel injection is performed at a slower timing (fuel cannot be combusted in the cylinder) and the fuel flows into the oil pan, causing engine oil dilution. To reduce the occurrence of this, post injection is performed twice.

|

1

|

Basic crank angle

|

|

2

|

CKP signal

|

|

3

|

5-stage injection (during fuel injection learning)

|

|

4

|

4-stage injection

|

|

5

|

3-stage injection

|

|

6

|

2-stage injection

|

|

7

|

Single injection

|

|

8

|

Pilot injection

|

|

9

|

Main injection

|

|

10

|

Follow-up injection

|

|

11

|

Post injection

|

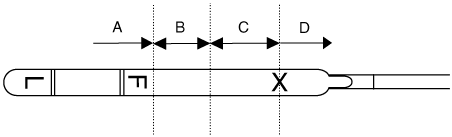

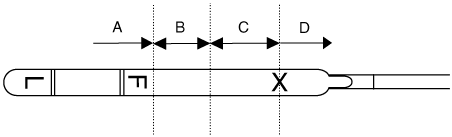

• If engine oil dilution due to post injection occurs, the diesel particulate filter indicator light flashes as shown in the following table according to the dilution amount. DTC P252F is stored in the PCM if the engine oil dilution amount reaches a certain level (specified value). If you find that this DTC is stored in the PCM while servicing, the vehicle may have been driven at a slow speed (low engine speed) for short distance frequently, and the diesel particulate filter auto regeneration may have been performed frequently. Therefore, alert the customer to change the driving method, such as by driving the vehicle at middle or high engine speeds for a longer distance.

If the diesel particulate filter indicator light flashes, DTC P253F is stored in the PCM. This indicates that engine oil performance and engine oil level is approaching the limit value due to the engine oil dilution amount.

If this happens, the fail-safe function (engine output restriction) operates to protect the engine, however, the engine could be damaged if the vehicle continues to be driven. Therefore, if the diesel particulate filter indicator light flashes and DTC P253F is stored in the PCM, replace the engine oil even if the engine oil level is lower than the X mark on the dipstick. Moreover, alert the customer to change the driving method, such as by driving the vehicle at middle or high engine speeds for a longer distance.

Replace the engine oil even though the engine oil level is at the X mark on the dipstick or higher.

After replacing the engine oil, reset the engine oil dilution value which is stored in the PCM using the Mazda Modular Diagnostic System (M-MDS).

-

Note

-

• The engine oil level (amount) shown in the following table is a reference. It may vary according to the engine oil temperature and elapsed period after the engine has been stopped. (The engine oil level shown in the table may differ from the actual level.)

|

Item

|

Engine oil dilution

|

|

Dipstick position (reference for engine oil dilution amount)

|

|

|

Dipstick position

|

A (Okay)

|

B

|

C

|

D (Over)

|

|

Diesel particulate filter indicator light

|

—

|

—

|

Flashes every 0.4 s (Warns user)

|

|

MIL

|

—

|

—

|

—

|

|

Output restriction

|

—

|

—

|

Max150 km/h {93 mph}

|

|

DTC recorded in PCM

|

P252F

|

P253F

|

|

User action

|

—

|

—

|

Bring the vehicle to a dealer

|

|

Diesel particulate filter auto regeneration range

|

—

|

—

|

Diesel particulate filter auto regeneration stops

|

|

Dealer action

|

—

|

—

|

If DTC P253F is stored in the PCM, replace the engine oil and reset the engine oil data using the Mazda Modular Diagnostic System (M-MDS) even if the engine oil level is lower than the X mark on the dipstick.

|

After inspecting engine oil level, replace engine oil and reset engine oil data using Mazda Modular Diagnostic System (M-MDS)

|

Operation condition

-

• The PCM determines the number of times fuel injection occurs based on the engine speed, fuel injection amount, and signals from each sensor.

• When the engine is started, the PCM calculates the number of times fuel injection occurs based on the engine coolant temperature and engine speed.