|

SOLENOID VALVE INSPECTION (PRIMARY CONTROL VALVE BODY)[FS5A-EL]

id051721807700

Resistance Inspection (On-Vehicle Inspection)

1. Remove the battery duct and battery cover. (See BATTERY REMOVAL/INSTALLATION[LF, L3].)

2. Disconnect the negative battery cable.

3. Remove the air cleaner component. (See INTAKE AIR SYSTEM REMOVAL/INSTALLATION[LF, L3].)

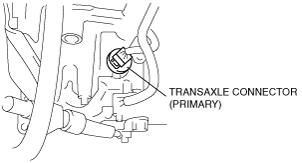

4. Disconnect the transaxle connector (primary).

am3zzw00003578

|

5. Measure the resistance between the following terminals.

am3zzw00003579

|

Primary control valve body (ATF temperature: –40—150 °C {–40—302 °F})

|

Terminal |

Solenoid valve |

Resistance (ohm) |

|---|---|---|

|

A—GND

|

Shift solenoid A

|

1.0—4.2

|

|

C—GND

|

Shift solenoid B

|

1.0—4.2

|

|

G—GND

|

Shift solenoid C

|

1.0—4.2

|

|

B—GND

|

Shift solenoid D

|

10.9—26.2

|

|

F—GND

|

Shift solenoid E

|

10.9—26.2

|

|

D—I

|

Pressure control solenoid A

|

2.4—7.3

|

6. Connect the transaxle connector (primary).

7. Install the air cleaner component. (See INTAKE AIR SYSTEM REMOVAL/INSTALLATION[LF, L3].)

8. Connect the negative battery cable.

9. Install the battery duct and battery cover. (See BATTERY REMOVAL/INSTALLATION[LF, L3].)

Operating Inspection

1. Disconnect the transaxle connector (primary).

2. Apply battery positive voltage to terminals A,B,C, F or G and battery negative voltage to GND, and verify that operating sound is heard from solenoid.

3. Apply battery positive voltage to terminal D and battery negative voltage to terminal I, and verify that operating sound is heard from solenoid.

am3zzw00003580

|

Resistance Inspection (Off‐Vehicle Inspection)

1. Remove the battery duct and battery cover. (See BATTERY REMOVAL/INSTALLATION[LF, L3].)

2. Disconnect the negative battery cable.

3. Remove the solenoid valve(s). (See SOLENOID VALVE REMOVAL/INSTALLATION (PRIMARY CONTROL VALVE BODY)[FS5A-EL].)

4. Measure the resistance of each solenoid valve individually.

5. Install the solenoid valve(s). (See SOLENOID VALVE REMOVAL/INSTALLATION (PRIMARY CONTROL VALVE BODY)[FS5A-EL].)

6. Connect the negative battery cable.

7. Install the battery duct and battery cover. (See BATTERY REMOVAL/INSTALLATION[LF, L3].)

Pressure control solenoid A

am3zzw00003457

|

Shift solenoid A, B, C

am3zzw00003458

|

Shift solenoid D, E

ampjjw00001463

|