|

ON-BOARD DIAGNOSTIC OPERATION

id092200103400

Malfunction Detection Function

DTC table

|

DTC |

Malfunction location |

Freeze frame data |

|---|---|---|

|

B1202

|

Fuel gauge sender unit circuit malfunction (open circuit)

|

—

|

|

B1204

|

Fuel gauge sender unit circuit malfunction (short to GND)

|

—

|

|

B1342

|

Instrument cluster malfunction

|

—

|

|

B2477

|

Configuration error

|

—

|

|

U0073

|

CAN system communication error (HS-CAN)

|

—

|

|

U0100

|

Communication error to PCM

|

×

|

|

U0101

|

Communication error to TCM

|

×

|

|

U0121

|

Communication error to ABS HU/CM or DSC HU/CM

|

×

|

|

U0131

|

Communication error to EHPAS control module

|

—

|

|

U0140

|

Communication error to PJB

|

×

|

|

U0151

|

Communication error to SAS control module

|

×

|

|

U0214

|

Communication error to keyless control module

|

×

|

|

U1900

|

Communication error to other module

|

×

|

|

U2023

|

Abnormal message from other module

|

×

|

|

U2064

|

Warning light illumination request signal from other modules

|

×

|

|

U2516

|

CAN system communication error (MS-CAN)

|

—

|

Freeze Frame Data

|

Freeze frame data |

Unit |

Note |

|---|---|---|

|

Malfunction type

|

—

|

• Communication errors of other units

• Abnormal messages from the PCM

• Warning light illumination request signal from other units

|

|

Illuminated warning light

|

—

|

Target warning light:

• Air bag system warning light

• Generator warning light

• MIL

• ABS warning light

• Brake system warning light

• AT warning light

• Keyless warning light

|

|

Meter, gauge control status

|

—

|

Target meter, gauge:

• Speedometer

• Tachometer

• Water temperature gauge

|

|

Traveled distance when DTC recorded

|

km

|

Only the last four digits are recorded

|

|

DTC cleared flag

|

Cleared/Not cleared

|

The freeze frame data will not be cleared even if the DTC data is cleared. If a DTC is cleared, a DTC cleared flag 'Cleared' is recorded with the corresponding freeze frame data.

|

DTCs and recorded freeze frame data

Warning light illumination request signal from other modules (U2064)

|

Freeze frame data |

Warning light illumination request unit |

|||||

|---|---|---|---|---|---|---|

|

PCM |

TCM |

ABS HU/CM DSC HU/CM |

SAS control module |

Keyless control module |

||

|

Illuminated warning light

|

Air bag system warning light

|

—

|

—

|

—

|

×

|

—

|

|

Generator warning light

|

×

|

—

|

—

|

—

|

—

|

|

|

MIL

|

×

|

—

|

—

|

—

|

—

|

|

|

ABS warning light

|

—

|

—

|

×

|

—

|

—

|

|

|

Brake system warning light

|

—

|

—

|

×

|

—

|

—

|

|

|

AT warning light

|

×

|

×

|

—

|

—

|

—

|

|

|

Keyless warning light

|

—

|

—

|

—

|

—

|

×

|

|

|

Meter, gauge control status

|

Speedometer

|

—

|

—

|

—

|

—

|

—

|

|

Tachometer

|

—

|

—

|

—

|

—

|

—

|

|

|

Water temperature gauge

|

—

|

—

|

—

|

—

|

—

|

|

Communication errors of other units (U0100, U0101, U0121, U0151, U0214)

|

Freeze frame data |

Unit that communication error occurs |

|||||

|---|---|---|---|---|---|---|

|

PCM (U0100) |

TCM (U0101) |

ABS HU/CM DSC HU/CM (U0121) |

Keyless control module (U0214) |

SAS control module (U0151) |

||

|

Illuminated warning light

|

Air bag system warning light

|

—

|

—

|

—

|

—

|

×

|

|

Generator warning light

|

×*

|

—

|

—

|

—

|

—

|

|

|

MIL

|

×*

|

—

|

—

|

—

|

—

|

|

|

ABS warning light

|

—

|

—

|

×

|

—

|

—

|

|

|

Brake system warning light

|

—

|

—

|

×

|

—

|

—

|

|

|

AT warning light

|

×

|

×

|

—

|

—

|

—

|

|

|

Keyless warning light

|

—

|

—

|

—

|

×

|

—

|

|

|

Meter, gauge control status

|

Speedometer

|

×

|

—

|

—

|

—

|

—

|

|

Tachometer

|

×

|

—

|

—

|

—

|

—

|

|

|

Water temperature gauge

|

×*

|

—

|

—

|

—

|

—

|

|

Abnormal messages from other module (U2023)

|

Freeze frame data |

PCM |

|

|---|---|---|

|

Illuminated warning light

|

Air bag system warning light

|

—

|

|

Generator warning light

|

—

|

|

|

MIL

|

×

|

|

|

ABS warning light

|

—

|

|

|

Brake system warning light

|

—

|

|

|

AT warning light

|

—

|

|

|

Keyless warning light

|

—

|

|

|

Meter, gauge control status

|

Speedometer

|

×

|

|

Tachometer

|

×

|

|

|

Water temperature gauge

|

×

|

|

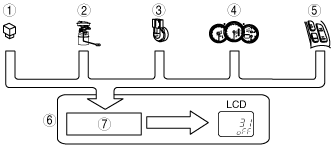

Input/Output Check Mode

Operation procedure

Input circuit check

|

Check code |

Parts sending input signal |

|---|---|

|

08

|

TNS relay

|

|

22

|

Fuel gauge sender unit

|

|

31

|

Key reminder switch (built into the ignition switch)

|

|

55

|

Dimmer switch (built into the instrument cluster)

|

|

62

|

• CAN system

• Cruise control switch

|

am3zzn00000740

|

|

1

|

TNS relay

|

|

2

|

Fuel gauge sender unit

|

|

3

|

Key reminder switch (ignition switch)

|

|

4

|

Dimmer switch

|

|

5

|

Cruise control switch

|

|

6

|

Instrument cluster

|

|

7

|

Microcomputer

|

Individual circuit check

|

Check code |

Parts sending input signal |

|---|---|

|

12

|

Speedometer

|

|

13

|

Tachometer

|

|

14

|

Buzzer

|

|

16

|

Fuel-level warning light

|

|

23

|

Fuel gauge

|

|

25

|

Water temperature gauge

|

|

26

|

LCD, warning and indicator light

|

|

32

|

Indicator buzzer

|

|

63

|

Seat belt reminder indicator

|

am3zzn00000741

|

|

1

|

Speedometer

|

|

2

|

Tachometer

|

|

3

|

Buzzer

|

|

4

|

Warning and indicator light

|

|

5

|

Fuel gauge

|

|

6

|

Water temperature gauge

|

|

7

|

Indicator buzzer

|

|

8

|

Seat belt reminder indicator

|

|

9

|

Microcomputer

|

PID/Data Monitor and Record

Monitor item table

|

Monitor item |

Input-output signal/part name |

Unit/State |

Terminal |

|

|---|---|---|---|---|

|

CCNT_HE

|

DTC

|

Number of continuous DTCs

|

—

|

|

|

ECT_GAUGE

|

Water temperature gauge

|

°F

|

°C

|

1I, 1K

|

|

NUMKEYS

|

Number of key ID numbers registered with the vehicle

|

—

|

—

|

|

|

ODO COUNT

|

Odometer

|

m

|

1I, 1K

|

|

|

RPM

|

Tachometer

|

rpm

|

||

|

SPEEDSG

|

Speedometer

|

mph

|

km/h

|

|