-

• If it exceeds the maximum specification, replace the cylinder block.

bes2ze00000114

bes2ze00000114

-

Maximum distortion, head gasket side of the cylinder block [Other than between cylinder bores]

-

0.10 mm {0.0039 in}

CYLINDER BLOCK INSPECTION

id011000507200

1. Measure the distortion of the following using a straight edge and feeler gauge.

bes2ze00000114

|

beshje00000094

|

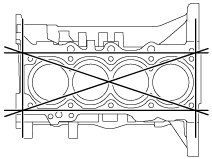

2. Measure the cylinder bore diameter using the cylinder gauge. The measurement position is in the X and Y directions at a point 50.6 mm {1.99 in} below the top surface of the cylinder as shown in the figure.

bes2ze00000191

|