|

am3zzn00003656

ON-BOARD DIAGNOSTIC SYSTEM MALFUNCTION DETECTION FUNCTION [PCM (FN4A-EL)]

id0502q2280100

Function

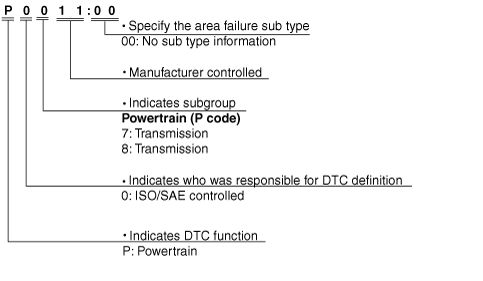

DTC 7-digit Code Definition

am3zzn00003656

|

DTC Table

|

DTC No. |

Definition |

Check engine light |

Automatic Transaxle warning light |

Drive cycle |

Pending code |

Freeze frame data |

|---|---|---|---|---|---|---|

|

P0500:00

|

VSS circuit malfunction

|

Illuminate

|

Illuminate

|

2

|

Available

|

Available

|

|

P0706:00

|

TR switch circuit range/performance

|

Illuminate

|

Illuminate

|

2

|

Available

|

Available

|

|

P0707:00

|

TR switch circuit low input

|

Illuminate

|

Illuminate

|

1

|

Available

|

Available

|

|

P0708:00

|

TR switch circuit high input

|

Illuminate

|

Illuminate

|

1

|

Available

|

Available

|

|

P0711:00

|

TFT sensor circuit range/performance

|

Illuminate

|

-

|

2

|

Available

|

Available

|

|

P0712:00

|

TFT sensor circuit low input

|

Illuminate

|

Illuminate

|

1

|

Available

|

Available

|

|

P0713:00

|

TFT sensor circuit high input

|

Illuminate

|

Illuminate

|

2

|

Available

|

Available

|

|

P0715:00

|

Input/turbine speed sensor circuit malfunction

|

Illuminate

|

Illuminate

|

1

|

Available

|

Available

|

|

P0731:00

|

Gear 1 incorrect ratio

|

-

|

Illuminate

|

1

|

-

|

-

|

|

P0732:00

|

Gear 2 incorrect ratio

|

-

|

Illuminate

|

1

|

-

|

-

|

|

P0733:00

|

Gear 3 incorrect ratio

|

-

|

Illuminate

|

1

|

-

|

-

|

|

P0734:00

|

Gear 4 incorrect ratio

|

-

|

Illuminate

|

1

|

-

|

-

|

|

P0741:00

|

TCC stuck off

|

-

|

Illuminate

|

1

|

-

|

-

|

|

P0742:00

|

TCC stuck on

|

-

|

Illuminate

|

1

|

-

|

-

|

|

P0744:00

|

TCC slip control malfunction

|

-

|

Illuminate

|

1

|

-

|

-

|

|

P0751:00

|

Shift solenoid A stuck off

|

Illuminate

|

Illuminate

|

2

|

Available

|

Available

|

|

P0752:00

|

Shift solenoid A stuck on

|

Illuminate

|

Illuminate

|

2

|

Available

|

Available

|

|

P0753:00

|

Shift solenoid A electrical malfunction

|

Illuminate

|

Illuminate

|

1

|

Available

|

Available

|

|

P0756:00

|

Shift solenoid B stuck off

|

Illuminate

|

Illuminate

|

2

|

Available

|

Available

|

|

P0757:00

|

Shift solenoid B stuck on

|

Illuminate

|

Illuminate

|

2

|

Available

|

Available

|

|

P0758:00

|

Shift solenoid B electrical malfunction

|

Illuminate

|

Illuminate

|

1

|

Available

|

Available

|

|

P0761:00

|

Shift solenoid C stuck off

|

Illuminate

|

Illuminate

|

2

|

Available

|

Available

|

|

P0762:00

|

Shift solenoid C stuck on

|

Illuminate

|

Illuminate

|

2

|

Available

|

Available

|

|

P0763:00

|

Shift solenoid C electrical malfunction

|

Illuminate

|

Illuminate

|

1

|

Available

|

Available

|

|

P0766:00

|

Shift solenoid D stuck off

|

Illuminate

|

Illuminate

|

2

|

Available

|

Available

|

|

P0768:00

|

Shift solenoid D electrical malfunction

|

Illuminate

|

Illuminate

|

1

|

Available

|

Available

|

|

P0771:00

|

Shift solenoid E stuck off

|

Illuminate

|

Illuminate

|

2

|

Available

|

Available

|

|

P0772:00

|

Shift solenoid E stuck on

|

Illuminate

|

Illuminate

|

2

|

Available

|

Available

|

|

P0773:00

|

Shift solenoid E electrical malfunction

|

Illuminate

|

Illuminate

|

1

|

Available

|

Available

|

|

P0883:00

|

Battery voltage high

|

Illuminate

|

Illuminate

|

1

|

Available

|

Available

|

|

P0884:00

|

Battery voltage low

|

Illuminate

|

Illuminate

|

1

|

Available

|

Available

|

|

P0894:00

|

Transaxle component slipping

|

-

|

Illuminate

|

1

|

-

|

-

|

|

P1712:00

|

Prevents the differential journal from burning or seizure

|

-

|

-

|

1

|

-

|

-

|

DTC Detection Condition

|

DTC No. |

Definition |

Detection condition |

|---|---|---|

|

P0500:00

|

VSS circuit malfunction

|

• Under the following conditions, the vehicle speed is 0.51 km/h {0.32 mph} or less for 4.5 s.

|

|

P0706:00

|

TR switch circuit range/performance

|

• Under the following conditions, no position signal from TR switch is detected for 100 s.

|

|

P0707:00

|

TR switch circuit low input

|

• The input voltage from TR switch is 0.493 V or less for 5 s when the input voltage from battery is 9 V or more.

|

|

P0708:00

|

TR switch circuit high input

|

• Under the following conditions, the input voltage from TR switch is 4.785 V or more for 5 s.

|

|

P0711:00

|

TFT sensor circuit range/performance

|

• Under the following conditions, a difference of the input voltage from TFT sensor is 29.3 mV or less.

|

|

P0712:00

|

TFT sensor circuit low input

|

• The input voltage from TFT sensor is 120 mV or less for 150 s.

|

|

P0713:00

|

TFT sensor circuit high input

|

• Under the following conditions, the input voltage from TFT sensor is 4.668 V or more for 1 s.

|

|

P0715:00

|

Input/turbine speed sensor circuit malfunction

|

• Under the following conditions, the turbine speed is 0 rpm for 775 ms.

|

|

P0731:00

|

Gear 1 incorrect ratio

|

• Under the following conditions, the gear ratio in 1GR is 2.19 or less for 1 s four times.

|

|

P0732:00

|

Gear 2 incorrect ratio

|

• Under the following conditions, the gear ratio in 2GR is 1.28 or less or 2.19 or more for 275 ms. After that, same conditions are met for 1 s three times.

|

|

P0733:00

|

Gear 3 incorrect ratio

|

• Under the following conditions, the gear ratio in 3GR is 1.40 to 1.70 for 2 s.

|

|

P0734:00

|

Gear 4 incorrect ratio

|

Condition A

• Under the following conditions, the gear ratio in 4GR is 0.57 or less or 1.28 or more for 1 s.

Condition B

• Under the following conditions, the gear ratio in 4GR is 0.91 to 1.09 for 1 s.

|

|

P0741:00

|

TCC stuck off

|

• Under the following conditions, the difference between the engine speed and turbine speed is 100 rpm or more for 5 s.

|

|

P0742:00

|

TCC stuck on

|

• Under the following conditions, the difference between the engine speed and turbine speed is 50 rpm or less for 5 s.

|

|

P0744:00

|

TCC slip control malfunction

|

• Under the following conditions, the gear ratio in 4GR is 0.61 or less or 0.79 or more for 100 ms.

|

|

P0751:00

|

Shift solenoid A stuck off

|

• Under the following conditions, the gear ratio in 4GR is incorrect (condition B).

|

|

P0752:00

|

Shift solenoid A stuck on

|

• The DTC P0894:00 is stored when the gear ratio in 4GR is correct.

|

|

P0753:00

|

Shift solenoid A electrical malfunction

|

• The output voltage to the shift solenoid A is stuck at 0 V or B+ when the solenoid valve operates according to PCM calculation.

|

|

P0756:00

|

Shift solenoid B stuck off

|

• Under the following conditions, the gear ratio in 1GR (D position) is incorrect.

|

|

P0757:00

|

Shift solenoid B stuck on

|

• Under the following conditions, the gear ratio in 2GR and gear ratio in 4GR (condition A) are incorrect.

|

|

P0758:00

|

Shift solenoid B electrical malfunction

|

• The output voltage to the shift solenoid B is stuck at 0 V or B+ when the solenoid valve operates according to PCM calculation.

|

|

P0761:00

|

Shift solenoid C stuck off

|

• Under the following conditions, the gear ratio in 1GR and gear ratio in 2GR are incorrect.

|

|

P0762:00

|

Shift solenoid C stuck on

|

• Under the following conditions, the gear ratio in 3GR is incorrect.

|

|

P0763:00

|

Shift solenoid C electrical malfunction

|

• Under the following conditions, the gear ratio in 1GR and gear ratio in 4GR (condition A) are incorrect.

|

|

P0766:00

|

Shift solenoid D stuck off

|

• Under the following conditions, the gear ratio in 1GR (M position) and gear ratio in 4GR (condition A) are incorrect.

|

|

P0768:00

|

Shift solenoid D electrical malfunction

|

• The output voltage to the shift solenoid D is stuck at 0 V or B+ when the solenoid valve operates according to PCM calculation.

|

|

P0771:00

|

Shift solenoid E stuck off

|

• Under the following conditions, the gear ratio in 1GR (M position) is incorrect and DTC P0741:00 is stored.

|

|

P0772:00

|

Shift solenoid E stuck on

|

• Under the following conditions, the DTC P0742:00 is stored.

|

|

P0773:00

|

Shift solenoid E electrical malfunction

|

• The output voltage to the shift solenoid E is stuck at 0 V or B+ when the solenoid valve operates according to PCM calculation.

|

|

P0883:00

|

Battery voltage high

|

• The input voltage from battery is 16.016 V or more for 5 s.

|

|

P0884:00

|

Battery voltage low

|

• The input voltage from battery is 8.25 V or less for 10 s when the engine speed is 500 rpm or more.

|

|

P0894:00

|

Transaxle component slipping

|

• Under the following conditions, the turbine speed is 187 rpm or more for 3 s.

|

|

P1712:00

|

Prevents the differential journal from burning or seizure

|

• Under the following conditions, a difference between rotation speed of left and right driving wheels is 490 rpm or more.

|

KOEO/KOER Self-test

KOEO (Key ON, Engine Off) self-test

KOEO (Key ON, Engine Running) self-test

Freeze Frame Data

Freeze frame data table

|

Freeze frame data item |

Unit |

Description |

Corresponding PID data monitor item |

|---|---|---|---|

|

FUELSYS1

|

Open Loop/Closed Loop/OL-Drive/OL-Fault/CL-Fault

|

Fuel system status

|

FUELSYS

|

|

LOAD

|

%

|

Calculated engine load

|

—

|

|

ECT

|

°C {°F}

|

Engine coolant temperature

|

ECT

|

|

SFT1

|

%

|

Short term fuel trim

|

SHRTFT1

|

|

LFT1

|

%

|

Long term fuel trim

|

LONGFT1

|

|

MAP

|

Pa {kgf/m2, psi}

|

Manifold absolute pressure

|

MAP

|

|

RPM

|

RPM

|

Engine speed

|

RPM

|

|

VS

|

KPH {MPH}

|

Vehicle speed

|

VSS

|

|

SPARKADV

|

°

|

Ignition timing

|

SPARKADV

|

|

IAT

|

°C {°F}

|

Intake air temperature

|

IAT

|

|

MAF

|

g/sec {lb/min}

|

Mass airflow

|

MAF

|

|

TP

|

%

|

Throttle valve position No.1

|

TP1

|

|

RUNTM

|

hh:mm:ss

|

Time from engine start

|

—

|

|

EGRPCT

|

%

|

Target EGR valve position

|

SEGRP_DSD

|

|

EVAPPCT

|

%

|

Purge solenoid valve controlled value

|

EVAPCP

|

|

WARMUPS

|

—

|

Number of warm-up cycle after DTC cleared

|

—

|

|

CLRDIST

|

Km {mile}

|

Mileage after DTC cleared

|

—

|

|

BARO

|

Pa {kgf/m2, psi}

|

Barometric pressure

|

BARO

|

|

CATTEMP11

|

°C {°F}

|

Estimated catalytic converter temperature

|

CATT11_DSD

|

|

VPWR

|

V

|

Module supply voltage

|

VPWR

|

|

ALV

|

%

|

Engine load

|

LOAD

|

|

TP_REL

|

%

|

Relative throttle position

|

TP REL

|

|

TP_B

|

%

|

Throttle valve position No.2

|

TP2

|

|

APP_D

|

%

|

Accelerator pedal position No.1

|

APP1

|

|

APP_E

|

%

|

Accelerator pedal position No.2

|

APP2

|

|

TAC_PCT

|

%

|

Target throttle valve position

|

ETC_DSD

|

Snapshot data table

|

Snapshot data item |

Unit |

Definition |

Corresponding PID data monitor item |

|---|---|---|---|

|

FUELSYS

|

OL/CL/OL-Drive/OL-Fault/CL-Fault

|

Fuel system status

|

FUELSYS

|

|

LOAD_C

|

%

|

Calculated engine load

|

—

|

|

ECT

|

°C {°F}

|

Engine coolant temperature

|

ECT

|

|

SHRTFT1

|

%

|

Short term fuel trim

|

SHRTFT1

|

|

LONGFT1

|

%

|

Long term fuel trim

|

LONGFT1

|

|

MAP

|

Pa {kgf/m2, psi}

|

Manifold absolute pressure

|

MAP

|

|

RPM

|

RPM

|

Engine speed

|

RPM

|

|

VSS

|

KPH {MPH}

|

Vehicle speed

|

VSS

|

|

SPARKADV

|

°

|

Ignition timing

|

SPARKADV

|

|

IAT

|

°C {°F}

|

Intake air temperature

|

IAT

|

|

MAF

|

g/sec {lb/min}

|

Mass airflow

|

MAF

|

|

TP1

|

%

|

Throttle valve position No.1

|

TP1

|

|

EG_RUN_TIME

|

—

|

Time from engine start

|

—

|

|

SEGRP_DSD

|

%

|

Target EGR valve position

|

SEGRP DSD

|

|

EVAPCP

|

%

|

Purge solenoid valve controlled value

|

EVAPCP

|

|

FLI

|

%

|

Fuel level in fuel tank

|

—

|

|

CLR_CNT

|

—

|

Number of warm-up cycle after DTC cleared

|

—

|

|

CLR_DIST

|

Km {mile}

|

Mileage after DTC cleared

|

—

|

|

FTP

|

Pa {kgf/m2, psi}

|

Fuel tank pressure

|

—

|

|

BARO

|

Pa {kgf/m2, psi}

|

Barometric pressure

|

BARO

|

|

CATT11_DSD

|

°C {°F}

|

Estimated catalytic converter temperature

|

CATT11_DSD

|

|

VPWR

|

V

|

Module supply voltage

|

VPWR

|

|

LOAD

|

%

|

Engine load

|

LOAD

|

|

EQ_RAT11_DSD

|

—

|

Target equivalence ratio (lambda)

|

EQ_RAT11_DSD

|

|

TP REL

|

%

|

Relative throttle position

|

TP REL

|

|

AAT

|

°C {°F}

|

Ambient air temperature

|

—

|

|

TP2

|

%

|

Throttle valve position No.2

|

TP2

|

|

APP1

|

%

|

Accelerator pedal position No.1

|

APP1

|

|

APP2

|

%

|

Accelerator pedal position No.2

|

APP2

|

|

ETC_DSD

|

%

|

Target throttle valve position

|

ETC_DSD

|