|

SECONDARY SHAFT COMPONENTS INSPECTION

id051500803500

Gears Inspection

1. Inspect the synchronizer cones for wear.

2. Inspect the gear teeth for damage, wear, and cracks.

3. Inspect the synchronizer ring matching teeth for damage and wear.

Synchronizer Ring Inspection

1. Inspect the synchronizer ring teeth for damage, wear, and cracks.

2. Inspect the tapered surface for wear and cracks.

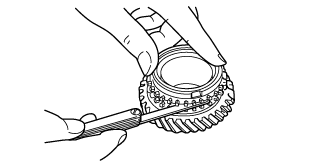

3. Measure the clearance between the synchronizer ring and the side of gear circumferentially using a feeler gauge.

bmgezm00000074

|

Clutch Hub Component Inspection

1. Inspect the clutch hub sleeve and hub operation.

2. Inspect the gear teeth for damage, wear, and cracks.

3. Inspect the synchronizer keys for damage, wear, and cracks.

4. Measure the clearance between the hub sleeve and shift fork.

bmgezm00000075

|

Secondary Shaft Gear Inspection

1. Inspect the gear contact surface for damage and wear.

2. Inspect the splines for damage and wear.

3. Inspect the gear teeth for damage, wear, and cracks.

4. Inspect the oil passage for clogging.

5. Measure the shaft gear runout.

bmgezm00000076

|

6. Measure the clearance between the shaft gears and the gears.

bmgezm00000077

|

1st and 2nd gear oil clearance (mm {in})

|

Gear |

Shaft (outer dia.) |

Gear (inner dia.) |

Clearance |

|---|---|---|---|

|

1st

|

39.445—39.470 {1.5530—1.5539}

|

39.500—39.525 {1.5552—1.5561}

|

0.030—0.080 {0.0012—0.0031}

|

|

2nd

|

34.945—34.965 {1.3758—1.3765}

|

35.015—35.035 {1.3786—1.3793}

|

0.050—0.090 {0.0020—0.0035}

|