|

bfw2za00000552

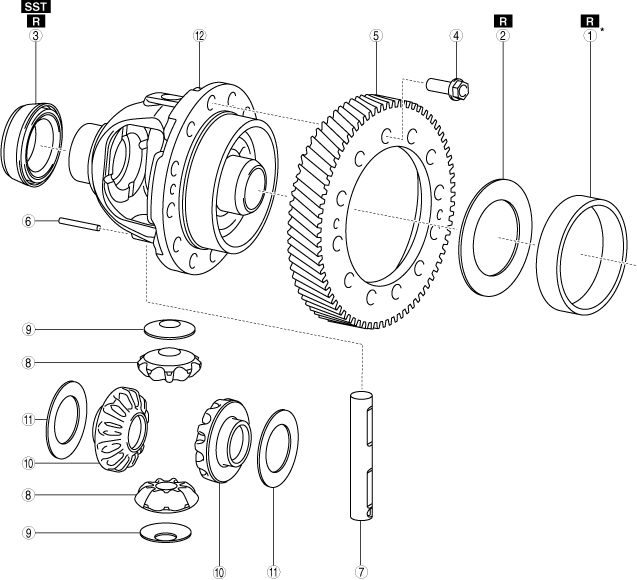

RING GEAR AND DIFFERENTIAL DISASSEMBLY [EW6A-EL/EW6AX-EL]

id0517006611l4

Structural View

bfw2za00000552

|

|

1

|

Bearing race*

|

|

2

|

Shim

|

|

3

|

Taper roller bearing

|

|

4

|

12 bolts

|

|

5

|

Ring gear

|

|

6

|

Pin

|

|

7

|

Pinion shaft

|

|

8

|

Pinion gear

|

|

9

|

Thrust washer

|

|

10

|

Side gear

|

|

11

|

Thrust washer

|

|

12

|

Differential gear case

|

Disassembly Procedure

1. Perform the following inspection:

2. Remove the bearing race and shim using a pin punch.

bfw2za00000094

|

bfw2za00000553

|

3. Remove the taper roller bearing using the following procedure:

bfw2za00000096

|

bfw2za00000097

|

bfw2za00000554

|

bfw2za00000099

|

4. Remove the ring gear using the following procedure:

bfw2za00000100

|

|

1

|

12 bolts

|

|

2

|

Ring gear

|

bfw2za00000101

|

bfw2za00000102

|

bfw2za00000099

|

bfw2za00000102

|

bfw2za00000555

|

bfw2za00000104

|

5. Remove the pin using the following procedure:

bfw2za00000105

|

bfw2za00000106

|

6. Remove the pinion shaft.

bfw2za00000108

|

7. Remove the pinion gears using the following procedure:

bfw2za00000109

|

bfw2za00000110

|

8. Remove the thrust washers from the pinion gears.

azzjjw00001492

|

9. Remove the side gears.

bfw2za00000111

|

10. Remove the thrust washers from the side gears.

azzjjw00001494

|

11. Clean the disassembled parts. (See AUTOMATIC TRANSAXLE CLEANING.)