|

am3zzn00003363

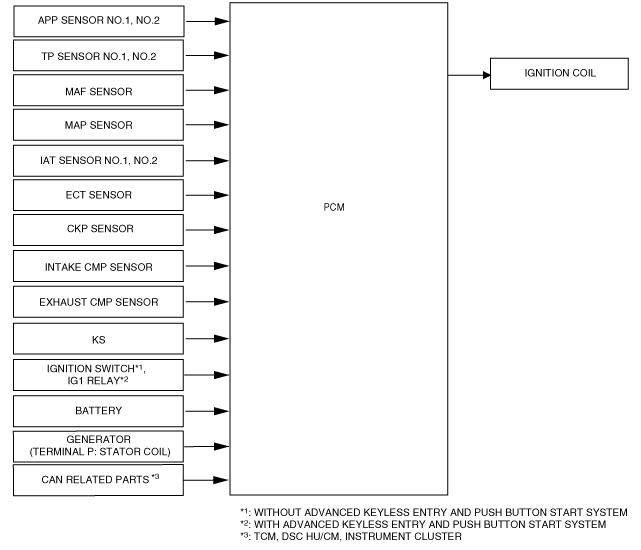

ELECTRONIC SPARK ADVANCE CONTROL [SKYACTIV-G 2.0]

id0140f4188200

Outline

Block Diagram

am3zzn00003363

|

Operation

Ignition method

|

Ignition method |

Ignition timing |

Ignition coil energization period |

|---|---|---|

|

Starting ignition

|

Determination based on engine coolant temperature

|

• Energization time to igniter (ignition coil energization time) is determined according to battery voltage

• Cylinder independent ignition

|

|

Cycle estimated ignition

|

Ignition at timing appropriate to engine operation conditions based on input signals

|

Timing chart

am3zzn00003421

|

Determination of Ignition Timing

am3uun00001983

|

|

Control zone |

Control condition |

Ignition method |

|---|---|---|

|

Engine start

|

Engine speed is less than 500 rpm

|

Engine starting

|

|

Idle zone

|

Accelerator pedal not depressed

|

(Cycle estimated ignition) (Determines ignition timing adding each correction to idle spark advance)

|

|

Normal zone

|

Engine operation except start and idling zones

|

(Cycle estimated ignition) (Determines ignition timing adding each correction to basic spark advance)

|

Ignition timing calculation method table

|

Contents

|

Calculation method or determination method for ignition timing, spark advance, and correction

|

Control zone

|

|||

|

|

|

|||

|

Starting ignition

|

Determination based on engine coolant temperature

|

A

|

|

|

|

|

Cycle estimated ignition

|

Idle spark advance

|

Set value according to target speed and charging efficiency*

|

|

A

|

|

|

Basic spark advance

|

Set value according to engine speed and charging efficiency*

|

|

|

A

|

|

|

Correction

|

Engine coolant temperature spark advance correction

|

Purpose: Ensures combustion stability when engine coolant temperature is low

According to engine coolant temperature

• High charging efficiency*, low engine coolant temperature→large correction

|

|

B

|

B

|

|

Warm-up promotion spark retard correction

|

Purpose: Activates the catalytic converter earlier

Approx. 50 s after engine start

• According to engine coolant temperature→correction

|

|

B

|

|

|

|

Feedback correction

|

Purpose: Ensures idling stability

While idling (inhibited during test mode)

• Large difference between actual engine speed and target engine speed→large correction

• Small difference between actual engine speed and target engine speed→small correction

|

|

B

|

|

|

|

Retard correction

|

Purpose: Reduces shift shock during down shifting

According to torque reduction request signal from TCM and DSC HU/CM

• Large torque reduction request during shifting→large correction

|

|

|

B

|

|

|

Deceleration fuel cut recovery retard correction

|

Purpose: Reduces shock during recovery from deceleration fuel cut

Recovery from deceleration fuel cut

• Difference between turbine speed and engine speed is larger→large correction

|

|

B

|

B

|

|

|

Acceleration spark retard correction

|

Purpose: Prevents knocking and shock during sudden acceleration

Acceleration when charging efficiency* volume increase (acceleration amount) is given value or more

• Large acceleration amount→large correction

|

|

|

B

|

|

|

Acceleration from standstill spark retard correction

|

Purpose: To prevent shock when the vehicle accelerates from a standstill

When vehicle accelerates from a standstill

• According to engine speed, throttle valve opening angle, accelerator, gear, clutch, engine coolant temperature and intake air temperature→correction

|

|

|

B

|

|

|

Knocking spark retard correction

|

Purpose: Knocking suppression

When knocking is detected while driving under a load

• Large amount of knocking→large correction

|

|

|

B

|

|

|

Valve timing correction

|

Purpose: Ensures combustion stability

When phase difference changes due to electric variable valve timing control and variable valve timing control

• Correction according to change in phase difference

|

|

|

B

|

|