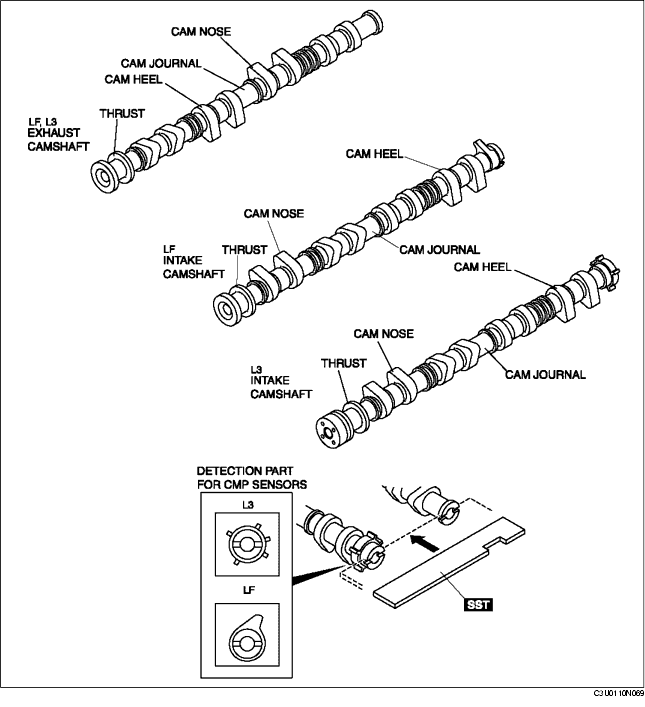

• A cast iron, highly rigid five axis journal camshaft has been adopted to insure higher reliability.

• Camshaft endplay is regulated at the flange of the No.1 journal.

• Lubricating oil is supplied through the oil supply hole at each journal. Additionally the cam nose part is chill cast to improve abrasion resistance, and the width of the cam heel part is shortened to reduce weight

• There is no positioning pin or key slot for the camshaft sprocket at the end of the camshaft.

• There is an oil line, by which the oil supplied to the variable valve timing actuator, located at the L3 engine models intake port side camshaft (front of camshaft).

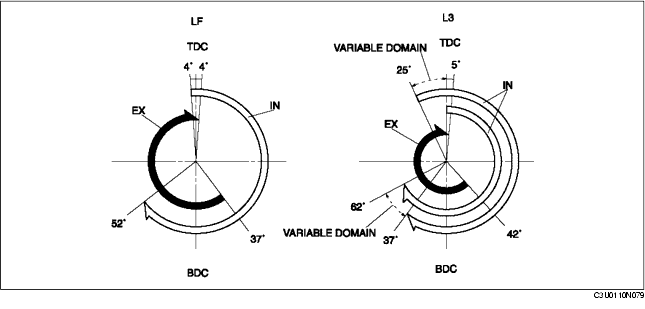

Camshaft Specification

|

ITEM

|

LF

|

L3

|

|||||||

|---|---|---|---|---|---|---|---|---|---|

|

IN

|

EX

|

IN

|

EX

|

||||||

|

LIFT

|

(mm {in})

|

8.8 {0.34}

|

7.7 {0.30}

|

9.1 {0.35}

|

7.8 {0.31}

|

||||

|

Overlap

|

(°)

|

8

|

5-30

|

||||||

• The detection unit or the camshaft position (CMP) sensor, which is integrated with the camshaft, is on the intake camshaft.

• The groove for securing the No.1 cylinder TDC for the camshaft, is provided at the rear of the intake and exhaust camshaft.

• The detection unit (trigger plate) for the camshaft position (CMP) sensor is at the intake port side camshaft for L3 (with variable valve timing mechanism) engine models.