PRIMARY SHAFT COMPONENTS INSPECTION

id051500803100

4th Gear, 3rd Gear Inspection

1. Inspect the synchronizer cones for wear.

-

• If there is any malfunction, replace parts if necessary.

2. Inspect the gear teeth for damage, wear, and cracks.

-

• If there is any malfunction, replace parts if necessary.

3. Inspect the synchronizer ring matching teeth for damage and wear.

-

• If there is any malfunction, replace the synchronizer ring.

4th Synchronizer Ring, 3rd Synchronizer Ring Inspection

1. Inspect the synchronizer ring teeth for damage, wear, and cracks.

-

• If there is any malfunction, replace parts if necessary.

2. Inspect the tapered surface for wear and cracks.

-

• If there is any malfunction, replace parts if necessary.

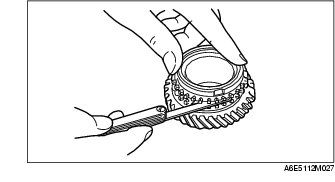

3. Measure the clearance between the synchronizer ring and the flank surface of the gear.

-

• If it is less than the minimum specification, replace the synchronizer ring.

-

Note

-

• Set the synchronizer ring squarely in the gear and measure around the circumference.

3rd and 4th gear synchronizer ring clearance

-

Standard: 1.50 mm {0.059 in}

-

Minimum: 0.80 mm {0.031 in}

3rd/4th Clutch Hub Component Inspection

1. Inspect the clutch hub sleeve and hub operation.

-

• If there is any malfunction, replace parts if necessary.

2. Inspect the gear teeth for damage, wear, and cracks.

-

• If there is any malfunction, replace parts if necessary.

3. Inspect the synchronizer keys for damage, wear, and cracks.

-

• If there is any malfunction, replace parts if necessary.

4. Measure the clearance between the hub sleeve and shift forks.

-

• If it exceeds the maximum specification, replace the hub sleeve and shift fork as a set.

3rd/4th clutch hub sleeve and shift fork clearance

-

Standard: 0.10-0.40 mm {0.004-0.015 in}

-

Maximum: 0.90 mm {0.035 in}

Primary Shaft Gear Inspection

1. Inspect the gear contact surface for damage and wear.

-

• If there is any malfunction, replace the primary shaft.

2. Inspect the splines for damage and wear.

-

• If there is any malfunction, replace the primary shaft.

3. Inspect the gear teeth for damage, wear, and cracks.

-

• If there is any malfunction, replace the primary shaft.

4. Inspect the oil passage for clogging.

-

• If there is any malfunction, replace the primary shaft.

5. Measure the shaft gear runout.

-

• If it exceeds the maximum specification, replace the primary shaft.

Primary shaft gear maximum runout

-

0.050 mm {0.0020 in}

6. Measure the clearance between the shaft gears and the gears.

-

• If not within the specification, replace parts if necessary.

3rd and 4th gear oil clearance (mm {in})

|

Gear

|

Shaft (Outer dia.)

|

Gear (Inner dia.)

|

Clearance

|

|

3rd

|

35.945-35.970 {1.415-1.416}

|

36.000-36.025 {1.417-1.418}

|

0.030-0.080 {0.001-0.003}

|

|

4th

|

30.945-30.970 {1.218-1.219}

|

31.000-31.025 {1.220-1.221}

|