FLYWHEEL INSPECTION [G35M-R]

id0510m1800100

1. Refer to CLUTCH UNIT REMOVAL/INSTALLATION to remove the flywheel. (See CLUTCH UNIT REMOVAL/INSTALLATION [G35M-R].)

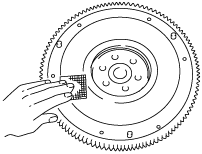

2. Inspect the flywheel for cracks, and the ring gear of the flywheel for damage and tooth wear.

-

3. Inspect the clutch disc surface of the flywheel for damage, loss, and discoloration.

-

• If there is any malfunction, correct slight scratches and discoloration using sandpaper.

4. Install the flywheel. (See CLUTCH UNIT REMOVAL/INSTALLATION [G35M-R].)

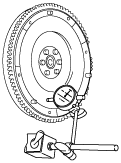

5. Install a dial gauge on the cylinder block.

6. Measure the runout of the surface that contacts the clutch disc using a dial gauge.

-

-

Flywheel maximum runout

-

0.1 mm {0.004 in}

7. Install in the reverse order of removal.

8. Add the specified amount of specified transaxle oil. (See TRANSAXLE OIL REPLACEMENT [G35M-R].)