|

OIL COOLER FLUSHING [FS5A-EL]

id051721801500

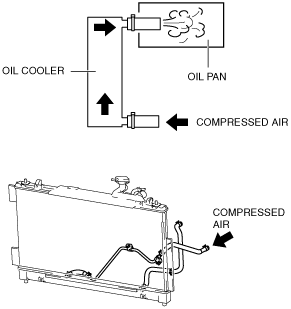

1. Disconnect the oil cooler hose. (See OIL COOLER REMOVAL/INSTALLATION [FS5A-EL].)

2. Set a clean oil pan up to the oil cooler hose inlet.

am6zzw00004898

|

3. Blow 491—882 kPa {5—9 kgf/cm2, 72—127 psi} of compressed air from the oil cooler hose outlet to drain remaining oil.

4. Add new ATF from the oil cooler hose outlet and blow 491—882 kPa {5—9 kgf/cm2, 72—127 psi} of compressed air to flush. (Repeat 2 or 3 times)

5. Verify that none of the following foreign material is mixed in with the drained ATF:

6. Repeat the procedures from Step 3 to 4 and flush the inside of the oil cooler.

7. If foreign material such as metal fragments or clutch facing remains even after the oil cooler is flushed repeatedly, replace the oil cooler (radiator). (See OIL COOLER REMOVAL/INSTALLATION [FS5A-EL].)