|

1

|

DETERMINE IF MALFUNCTION CAUSE IS IMMOBILIZER SYSTEM OR OTHER

• Are any of the following conditions present?

-

― Engine does not start completely.

― PCM DTC P1260:00 is displayed.

|

Yes

|

Both conditions present:

• Go to Step 4.

|

|

No

|

Either or other condition present:

• Go to the next step.

|

|

2

|

INSPECT PUSH BUTTON START CONNECTOR CONNECTION

• Inspect the connection of push button start connector.

• Is the push button start connector securely connected to the coil antenna?

|

Yes

|

Go to the next step.

|

|

No

|

Reconnect the push button start securely, then repeat from Step 1.

|

|

3

|

DETERMINE IF MALFUNCTION CAUSE IS INSTRUMENT CLUSTER OR OTHER

• Switch the ignition ON (engine off).

• Does the security indicator light illuminate?

|

Yes

|

Go to the next step.

|

|

No

|

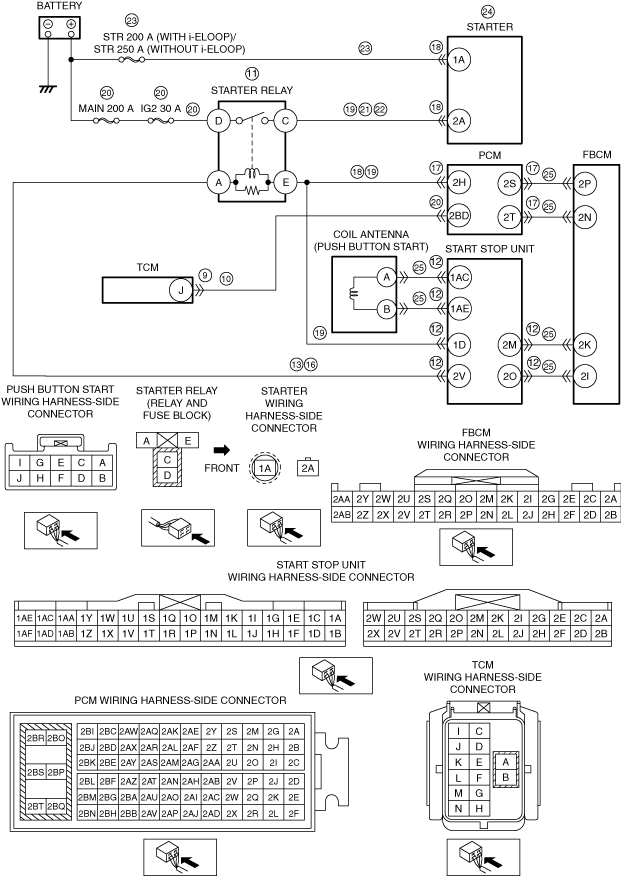

Inspect the wiring harness between the following terminals:

• Instrument cluster terminal B—Front body control module (FBCM) terminal 2K

• Instrument cluster terminal D—Front body control module (FBCM) terminal 2I

• Front body control module (FBCM) terminal 2P—PCM terminal 2S

• Front body control module (FBCM) terminal 2N—PCM terminal 2T

-

― If there is any malfunction:

-

• Repair or replace the malfunctioning part according to the inspection results, then go to Step 28.

• Inspect the instrument cluster

-

― If there is any malfunction:

-

• Repair or replace the malfunctioning part according to the inspection results, then go to Step 28.

|

|

4

|

VERIFY IMMOBILIZER SYSTEM DTC

• Retrieve the immobilizer system DTC using the M-MDS.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Go to the next step.

|

|

5

|

DETERMINE IF MALFUNCTION CAUSE IS i-stop SYSTEM OR OTHER

• Verify the symptom.

• Does the engine not restart while the i-stop function is operating?.

|

Yes

|

Perform the symptom troubleshooting "NO.6 ENGINE DOES NOT RESTART".

|

|

No

|

Go to the next step.

|

|

6

|

VERIFY PCM DTC

• Retrieve any DTCs using the M-MDS.

• Are any continuous memory DTCs present?

|

Yes

|

Continuous memory DTC is displayed:

• Go to the applicable DTC inspection.

Communication error message is displayed:

• Inspect the following:

-

― Open circuit in wiring harness between main relay terminal E and PCM terminal 2B

― Open circuit in wiring harness between main relay terminal C and PCM terminal 2BO or 2BR

― Main relay (stuck open)

― Open or short circuit in wiring harness between DLC-2 and PCM terminal 2S or 2T

― Open or poor ground circuit (PCM terminal 2BQ and 2BT)

― Poor connection of vehicle body ground

• Repair or replace the malfunctioning part according to the inspection results.

|

|

No

|

Go to the next step.

|

|

7

|

INSPECT POWER SUPPLY

• Access the VPWR PID using the M-MDS.

• Verify the VPWR PID value.

• Is the VPWR PID value B+?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the following:

• Battery connection

-

― If there is any malfunction:

-

• Repair or replace the malfunctioning part according to the inspection results, then repeat this step.

|

|

8

|

DETERMINE IF MALFUNCTION CAUSE IS STARTER RELAY CONTROL SIGNAL CIRCUIT OR OTHER

• Switch the ignition to START.

• Is a clicking sound heard from the starter relay?

|

Yes

|

Go to Step 18.

|

|

No

|

Go to the next Step.

|

|

9

|

INSPECT TCM CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the TCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then repeat Step 8.

|

|

No

|

Go to the next step.

|

|

10

|

INSPECT TCM CIRCUIT FOR OPEN CIRCUIT

• Verify that the TCM connector is disconnected.

• Inspect for continuity between TCM terminal J (wiring harness-side) and PCM terminal 2BD (wiring harness-side).

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between TCM terminal J and PCM terminal 2BD.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Repeat Step 8.

|

|

11

|

INSPECT STARTER RELAY

• Remove the starter relay.

• Inspect the starter relay.

• Is there any malfunction?

|

Yes

|

Replace the starter relay.

Repeat Step 8.

|

|

No

|

Go to the next step.

|

|

12

|

INSPECT START STOP UNIT CONNECTOR CONDITION

• Disconnect the start stop unit connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then repeat Step 8.

|

|

No

|

Go to the next step.

|

|

13

|

INSPECT STARTER RELAY CONTROL CIRCUIT FOR SHORT TO GROUND

• Starter relay is removed.

• Verify that the start stop unit connector is disconnected.

• Inspect for continuity between starter relay terminal A (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between starter relay terminal A and start stop unit terminal 2V.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to ground.

Repeat Step 8.

|

|

No

|

Go to the next step.

|

|

14

|

INSPECT STARTER RELAY CONTROL CIRCUIT FOR OPEN CIRCUIT

• Starter relay is removed.

• Verify that the start stop unit connector is disconnected.

• Inspect for continuity between starter relay terminal A (wiring harness-side) and start stop unit terminal 2V (wiring harness-side).

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between starter relay terminal A and start stop unit terminal 2V.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Repeat Step 8.

|

|

15

|

INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then repeat Step 8.

|

|

No

|

Go to the next step.

|

|

16

|

INSPECT STARTER RELAY CONTROL CIRCUIT FOR SHORT TO GROUND

• Starter relay is removed.

• Verify that the start stop unit and PCM connectors are disconnected.

• Inspect for continuity between starter relay terminal E (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Starter relay terminal E—PCM terminal 2H

• Starter relay terminal E—Start stop unit terminal 1D

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to ground.

Repeat Step 8.

|

|

No

|

Go to the next step.

|

|

17

|

INSPECT STARTER RELAY CONTROL CIRCUIT FOR OPEN CIRCUIT

• Starter relay is removed.

• Verify that the start stop unit and PCM connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side):

-

― Starter relay terminal E—PCM terminal 2H

― Starter relay terminal E—Start stop unit terminal 1D

• Is there continuity?

|

Yes

|

Inspect the start stop unit.

• If there is any malfunction:

-

― Replace the start stop unit, then repeat Step 8.

• If there is no malfunction:

-

― Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Starter relay terminal E—PCM terminal 2H

• Starter relay terminal E—Start stop unit terminal 1D

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Repeat Step 8.

|

|

18

|

INSPECT STARTER CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the starter connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is the connector normal?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the connector and/or terminals, then go to Step 28.

|

|

19

|

DETERMINE IF MALFUNCTION CAUSE IS STARTER OR OTHER

• Verify that the starter connector is disconnected.

• Crank the engine.

• Measure the voltage at the starter terminal 2A (wiring harness-side)

• Is the voltage B+?

|

Yes

|

Go to Step 23.

|

|

No

|

Go to the next step.

|

|

20

|

INSPECT FOR SHORT TO GROUND AND OPEN CIRCUIT IN SECONDARY (STARTER POWER SUPPLY) OF STARTER RELAY

• Switch the ignition off.

• Remove the starter relay.

• Verify that the starter connector is disconnected.

• Measure the voltage at the starter relay terminal D (wiring harness-side)

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the MAIN 200 A fuse and IG2 30 A fuse.

• If the fuse is blown:

-

― Repair or replace the wiring harness for a possible short to ground.

― Replace the malfunctioning fuse.

• If the fuse is deteriorated:

-

― Replace the malfunctioning fuse.

• If all fuses are normal:

-

― Repair or replace the wiring harness for a possible open circuit.

Go to Step 28.

|

|

21

|

INSPECT STARTER POWER SUPPLY CIRCUIT FOR SHORT TO GROUND

• Verify that the starter relay is removed.

• Verify that the starter connector is disconnected.

• Inspect for continuity between starter relay terminal C (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Repair or replace the wiring harness, then go to Step 28.

|

|

No

|

Go to the next step.

|

|

22

|

INSPECT STARTER POWER SUPPLY CIRCUIT FOR OPEN CIRCUIT

• Verify that the starter relay is removed.

• Verify that the starter connector is disconnected.

• Inspect for continuity between starter relay terminal C (wiring harness-side) and starter terminal 2A (wiring harness-side).

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Repair or replace the wiring harness, then go to Step 28.

|

|

23

|

INSPECT STARTER POWER SUPPLY CIRCUIT FOR SHORT TO GROUND OR OPEN CIRCUIT

• Verify that the starter connector is disconnected.

• Switch the ignition off.

• Measure the voltage at the starter terminal 1A (wiring harness-side)

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the STR 200 A (with i-ELOOP)/ STR 250 A (without i-ELOOP) fuse.

• If the fuse is blown:

-

― Repair or replace the wiring harness for a possible short to ground.

― Replace the fuse.

• If the fuse is deteriorated:

-

― Replace the fuse.

• If the fuse is normal:

-

― Repair or replace the wiring harness for a possible open circuit.

Go to Step 28.

|

|

24

|

INSPECT STARTER

• Is the starter normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the starter, then go to Step 28.

|

|

25

|

INSPECT IMMOBILIZER SYSTEM RELATED CIRCUIT

• Inspect the following wiring harness and connectors:

-

― Between push button start terminal A and start stop unit terminal 1AC

― Between push button start terminal B and start stop unit terminal 1AE

― Between start stop unit terminal 2M—Front body control module (FBCM) terminal 2K

― Between start stop unit terminal 2O—Front body control module (FBCM) terminal 2I

― Between front body control module (FBCM) terminal 2P—PCM terminal 2S

― Between front body control module (FBCM) terminal 2N—PCM terminal 2T

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

No

|

Go to the next step.

|

|

26

|

VERIFY PRESENT MALFUNCTION DTC

• Perform the KOEO self test.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

Go to the next step.

|

|

27

|

DETERMINE IF MALFUNCTION CAUSE IS BASE ENGINE OR OTHER

• Inspect for a seized drive plate.

• Is the drive plate seized?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results.

|

|

No

|

Base engine malfunction or engine damage during compression due to liquid (such as water, fuel, or engine oil) penetration into cylinder.

• Overhaul or replace the engine.

|

|

28

|

Verify the test results.

• If normal, return to the diagnostic index to service any additional symptoms.

• If the malfunction remains, inspect the related Service Bulletins and/or On-line Repair Information and perform repair or diagnosis.

-

― If the vehicle is repaired, troubleshooting is completed.

― If the vehicle is not repaired or additional diagnostic information is not available, reprogram the PCM if a later calibration is available. Retest.

|