|

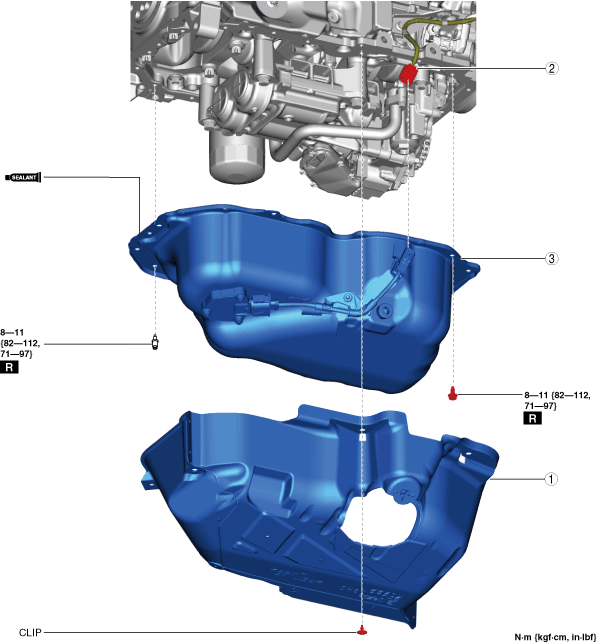

OIL PAN REMOVAL/INSTALLATION [SKYACTIV-D 2.2]

id0111s6800200

Replacement Part

|

Bolt

Quantity: 19 (Type A, B)

Location of use: Oil pan

|

Oil and Chemical Type

|

Silicone sealant

Type:TB1217D or equivalent

|

1. Turn the steering wheel completely to the right.

2. Disconnect the negative battery terminal. (See NEGATIVE BATTERY TERMINAL DISCONNECTION/CONNECTION.)

3. Remove the front under cover No.2. (See FRONT UNDER COVER No.2 REMOVAL/INSTALLATION.)

4. Remove the front splash shield (RH). (See SPLASH SHIELD REMOVAL/INSTALLATION.)

5. Drain the engine oil. (See ENGINE OIL REPLACEMENT [SKYACTIV-D 2.2].)

6. Remove in the order indicated in the table.

7. Install in the reverse order of removal.

8. Refill with the specified type and amount of the engine oil. (See ENGINE OIL REPLACEMENT [SKYACTIV-D 2.2].)

9. Start the engine and confirm that there is no oil leakage.

10. Inspect the oil level. (See ENGINE OIL LEVEL INSPECTION [SKYACTIV-D 2.2].)

ac5uuw00008460

|

|

1

|

Seal plate

(See Seal Plate Installation Note.)

|

|

2

|

Emission wiring harness connector

|

|

3

|

Oil pan

(See Oil Pan Removal Note.)

(See Oil Pan Installation Note.)

|

Emission Wiring Harness Connector Removal Note

1. Disconnect the emission wiring harness connector.

ac5uuw00008461

|

Oil Pan Removal Note

1. Remove the oil pan using a separator tool.

ac5wzw00007098

|

2. When replacing the oil pan, remove the short-cord. (See ENGINE OIL LEVEL SENSOR REMOVAL/INSTALLATION [SKYACTIV-D 2.2].)

Oil Pan Installation Note

1. When replacing the oil pan, install the short-cord and a new engine oil level sensor. (See ENGINE OIL LEVEL SENSOR REMOVAL/INSTALLATION [SKYACTIV-D 2.2].)

2. Completely clean and remove any oil, dirt, sealant or other foreign matter that may be adhering to the cylinder block and oil pan.

3. Apply silicone sealant (TB1217D or equivalent) to the oil pan and the cylinder block.

Oil pan

ac5uuw00009307

|

Cylinder block

ac5wzw00007108

|

4. Install the oil pan to the cylinder block.

ac5wzw00007107

|

5. Install the oil pan using the following procedure:

ac5wzw00007101

|

ac5wzw00007102

|

ac5wzw00007103

|

Seal Plate Installation Note

1. Install the seal plate using the following procedure:

ac5wzw00007104

|

ac5wzw00007105

|