|

ac5uuw00009003

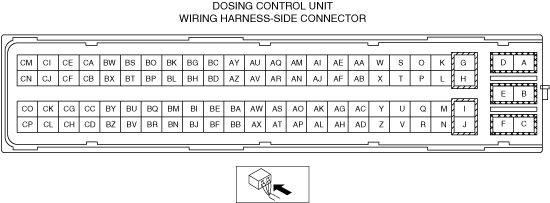

DOSING CONTROL UNIT INSPECTION [SKYACTIV-D 2.2]

id0140z7824100

Without Using The M-MDS

Terminal voltage table (Reference)

ac5uuw00009003

|

|

Terminal |

Signal |

Connected to |

Test condition |

Voltage (V) |

inspection item |

|---|---|---|---|---|---|

|

A

|

Battery voltage

|

SCR relay No.2

|

Switch the ignition ON (engine off)

|

B+

|

• SCR relay No.2

• Related wiring harness

|

|

B

|

Battery voltage

|

SCR relay No.1, No.2

|

Switch the ignition ON (engine off)

|

B+

|

• SCR relay No.1, No.2

• Related wiring harness

|

|

C

|

Battery voltage

|

SCR relay No.1, No.2

|

Switch the ignition ON (engine off)

|

B+

|

• SCR relay No.1, No.2

• Related wiring harness

|

|

D

|

Urea tank heater control

|

Urea tank heater

|

Urea tank heater operating

|

B+

|

• Urea tank heater

• Related wiring harness

|

|

Urea tank heater not operating

|

Below 1.0

|

||||

|

E

|

GND

|

GND

|

Under any condition

|

Below 1.0

|

• Related wiring harness

|

|

F

|

Urea hose heater control

|

Urea hose heater

|

Urea hose heater operating

|

B+

|

• Urea hose heater

• Related wiring harness

|

|

Urea hose heater not operating

|

Below 1.0

|

||||

|

G

|

—

|

—

|

—

|

—

|

—

|

|

H

|

DEF pump control (GND)

|

DEF pump (pumping side)

|

Depend on engine load

|

Below 1.0

|

• DEF pump

• Related wiring harness

|

|

I

|

DEF pump control (battery voltage)

|

DEF pump (pumping side)

|

Depend on engine load

|

0—B+

|

• DEF pump

• Related wiring harness

|

|

J

|

—

|

—

|

—

|

—

|

—

|

|

K

|

Urea injector control (-)

|

Urea injector

|

Depend on engine load

|

Below 1.0

|

• Urea injector

• Related wiring harness

|

|

L

|

Battery voltage

|

Urea level sensor/urea temperature sensor

|

Switch the ignition ON (engine off)

|

B+

|

• Urea level sensor/urea temperature sensor

• Related wiring harness

|

|

M

|

—

|

—

|

—

|

—

|

—

|

|

N

|

Urea injector control (+)

|

Urea injector

|

Depend on engine load

|

0—B+

|

• Urea injector

• Related wiring harness

|

|

O

|

—

|

—

|

—

|

—

|

—

|

|

P

|

—

|

—

|

—

|

—

|

—

|

|

Q

|

—

|

—

|

—

|

—

|

—

|

|

R

|

—

|

—

|

—

|

—

|

—

|

|

S

|

—

|

—

|

—

|

—

|

—

|

|

T

|

Battery voltage

|

DEF quality sensor

|

Switch the ignition ON (engine off)

|

B+

|

• DEF quality sensor

• Related wiring harness

|

|

U

|

—

|

—

|

—

|

—

|

—

|

|

V

|

—

|

—

|

—

|

—

|

—

|

|

W

|

—

|

—

|

—

|

—

|

—

|

|

X

|

—

|

—

|

—

|

—

|

—

|

|

Y

|

DEF pump control (battery voltage)

|

DEF pump (siphoning side)

|

Depend on engine load

|

0—B+

|

• DEF pump

• Related wiring harness

|

|

Z

|

—

|

—

|

—

|

—

|

—

|

|

AA

|

—

|

—

|

—

|

—

|

—

|

|

AB

|

—

|

—

|

—

|

—

|

—

|

|

AC

|

—

|

—

|

—

|

—

|

—

|

|

AD

|

—

|

—

|

—

|

—

|

—

|

|

AE

|

—

|

—

|

—

|

—

|

—

|

|

AF

|

—

|

—

|

—

|

—

|

—

|

|

AG

|

—

|

—

|

—

|

—

|

—

|

|

AH

|

—

|

—

|

—

|

—

|

—

|

|

AI

|

—

|

—

|

—

|

—

|

—

|

|

AJ

|

—

|

—

|

—

|

—

|

—

|

|

AK

|

—

|

—

|

—

|

—

|

—

|

|

AL

|

—

|

—

|

—

|

—

|

—

|

|

AM

|

—

|

—

|

—

|

—

|

—

|

|

AN

|

—

|

—

|

—

|

—

|

—

|

|

AO

|

—

|

—

|

—

|

—

|

—

|

|

AP

|

—

|

—

|

—

|

—

|

—

|

|

AQ

|

—

|

—

|

—

|

—

|

—

|

|

AR

|

Urea level/urea temperature control

|

Urea level sensor/urea temperature sensor

|

Because this terminal is for PWM (Pulse Width Modulation) signal, integrity determination by terminal voltage is not possible.

|

• Urea level sensor/urea temperature sensor

• Related wiring harness

|

|

|

AS

|

—

|

—

|

—

|

—

|

—

|

|

AT

|

—

|

—

|

—

|

—

|

—

|

|

AU

|

—

|

—

|

—

|

—

|

—

|

|

AV

|

GND

|

Urea level sensor/urea temperature sensor

|

Switch the ignition ON (engine off)

|

Below 1.0

|

• Urea level sensor/urea temperature sensor

• Related wiring harness

|

|

AW

|

—

|

—

|

—

|

—

|

—

|

|

AX

|

—

|

—

|

—

|

—

|

—

|

|

AY

|

—

|

—

|

—

|

—

|

—

|

|

AZ

|

—

|

—

|

—

|

—

|

—

|

|

BA

|

DEF quality sensor control (SENT signal)

|

DEF quality sensor

|

Because this terminal is for SENT communication, integrity determination by terminal voltage is not possible.

|

• DEF quality sensor

• Related wiring harness

|

|

|

BB

|

—

|

—

|

—

|

—

|

—

|

|

BC

|

—

|

—

|

—

|

—

|

—

|

|

BD

|

—

|

—

|

—

|

—

|

—

|

|

BE

|

GND

|

DEF quality sensor

|

Switch the ignition ON (engine off)

|

Below 1.0

|

• DEF quality sensor

• Related wiring harness

|

|

BF

|

—

|

—

|

—

|

—

|

—

|

|

BG

|

—

|

—

|

—

|

—

|

—

|

|

BH

|

—

|

—

|

—

|

—

|

—

|

|

BI

|

—

|

—

|

—

|

—

|

—

|

|

BJ

|

—

|

—

|

—

|

—

|

—

|

|

BK

|

CAN_H

|

CAN system related modules

|

Because this terminal is for CAN, integrity determination by terminal voltage is not possible.

|

• Related wiring harness

|

|

|

BL

|

CAN_L

|

CAN system related modules

|

Because this terminal is for CAN, integrity determination by terminal voltage is not possible.

|

• Related wiring harness

|

|

|

BM

|

—

|

—

|

—

|

—

|

—

|

|

BN

|

—

|

—

|

—

|

—

|

—

|

|

BO

|

—

|

—

|

—

|

—

|

—

|

|

BP

|

Ignition (IG1)

|

IG1 relay

|

Switch the ignition ON (engine off)

|

B+

|

• IG1 relay

• Related wiring harness

|

|

BQ

|

—

|

—

|

—

|

—

|

—

|

|

BR

|

—

|

—

|

—

|

—

|

—

|

|

BS

|

—

|

—

|

—

|

—

|

—

|

|

BT

|

—

|

—

|

—

|

—

|

—

|

|

BU

|

—

|

—

|

—

|

—

|

—

|

|

BV

|

SCR relay No.1 control

|

SCR relay No.1

|

Switch the ignition ON (engine off)

|

B+

|

• SCR relay No.1

• Related wiring harness

|

|

BW

|

—

|

—

|

—

|

—

|

—

|

|

BX

|

—

|

—

|

—

|

—

|

—

|

|

BY

|

—

|

—

|

—

|

—

|

—

|

|

BZ

|

—

|

—

|

—

|

—

|

—

|

|

CA

|

—

|

—

|

—

|

—

|

—

|

|

CB

|

—

|

—

|

—

|

—

|

—

|

|

CC

|

—

|

—

|

—

|

—

|

—

|

|

CD

|

—

|

—

|

—

|

—

|

—

|

|

CE

|

—

|

—

|

—

|

—

|

—

|

|

CF

|

—

|

—

|

—

|

—

|

—

|

|

CG

|

—

|

—

|

—

|

—

|

—

|

|

CH

|

—

|

—

|

—

|

—

|

—

|

|

CI

|

—

|

—

|

—

|

—

|

—

|

|

CJ

|

—

|

—

|

—

|

—

|

—

|

|

CK

|

—

|

—

|

—

|

—

|

—

|

|

CL

|

—

|

—

|

—

|

—

|

—

|

|

CM

|

—

|

—

|

—

|

—

|

—

|

|

CN

|

DEF pump control (GND)

|

DEF pump (siphoning side)

|

Depend on engine load

|

Below 1.0

|

• DEF pump

• Related wiring harness

|

|

CO

|

—

|

—

|

—

|

—

|

—

|

|

CP

|

—

|

—

|

—

|

—

|

—

|

Using The M-MDS

1. Connect the M-MDS to the DLC-2.

2. Switch the ignition ON (engine off).

3. Measure the PID value.

Simulation item table

|

Item (definition) |

Definition |

Unit/Condition |

|---|---|---|

|

HTR_TANK

|

Urea tank heater

|

Off/On

|

|

REDUCT_INJ_DC

|

Reductant injector duty cycle

|

%

|

|

REV_VALVE

|

Urea reverting valve

|

Off/On

|

PID/DATA monitor item table

|

Item (definition) |

Definition |

Unit/Condition |

|---|---|---|

|

A_SCR_C_TMP

|

Average SCR catalyst temperature

|

°C, °F

|

|

ACT_SLO_PMP

|

Actuator test solenoid pump

|

— (times)

|

|

BOOP_MCC

|

Boost pressure monitor completion condition counts

|

— (Undefined/Not Used)

|

|

BOOP_MCEC

|

Boost pressure monitor conditions encountered counts

|

— (Undefined/Not Used)

|

|

C_T_B1S2

|

Exhaust gas temperature sensor No.2

|

°C, °F

|

|

CL_NMHC_MN_CP

|

Catalyst monitoring completed / NMHC catalyst monitoring completed

|

—

|

|

CMP_MNT_ENA

|

Comprehensive component monitoring enabled

|

—

|

|

COMP3_MNT

|

Comprehensive component monitoring completed

|

—

|

|

CONF_URA_TK_LV

|

Configuration for urea tank level

|

—

|

|

CP_IGN_SP

|

Compression ignition monitoring supported

|

—

|

|

CTLY_NMHC_MN

|

Catalyst monitoring / NMHC catalyst monitoring

|

—

|

|

CTRL_MOD_VOL

|

Control module voltage

|

V

|

|

DC_PWM_O_PS_UV

|

Dutycycle of the PWM signal output to the power stage of urea dosing valve

|

%

|

|

DIS_ACT_MIL

|

Distance traveled while check engine light is activated

|

km, ft, mi

|

|

DIS_CLR_DTC

|

Distance Since DTCs cleared

|

km, ft, mi

|

|

DPES_DS_NOX

|

Dew point end signal for downstream NOx sensor

|

—

|

|

DPES_PM

|

Dew point end signal for PM sensor

|

—

|

|

DPES_US_NOX

|

Dew point end signal for upstream NOx sensor

|

—

|

|

DSR_D_AMO

|

Desired dosing amount

|

— (mg/s)

|

|

EG_MF

|

Exhaust gas mass flow

|

— (kg/h)

|

|

EGR_VVT_MCC

|

EGR and/or VVT monitor completion condition counts

|

— (Undefined/Not Used)

|

|

EGR_VVT_MCEC

|

EGR and/or VVT monitor conditions encountered counts

|

— (Undefined/Not Used)

|

|

EGR_VVT_MN_CP

|

EGR and/or VVT system monitoring completed

|

—

|

|

EGR_VVT_MNT

|

EGR and/or VVT system monitoring

|

—

|

|

EGS_MCC

|

Gas sensor monitor completion counts

|

— (Undefined/Not Used)

|

|

EGS_MCEC

|

Exhaust gas sensor monitor conditions encountered counts

|

— (Undefined/Not Used)

|

|

EIAECD1_TT_SUP

|

Total run time with EI-AECD #1 active supported

|

—

|

|

EIAECD1_TT_TM1

|

Total run time with EI-AECD #1 Timer 1 active

|

hh:mm:ss

|

|

EIAECD1_TT_TM2

|

Total run time with EI-AECD #1 Timer 2 active

|

hh:mm:ss

|

|

EIAECD2_TT_SUP

|

Total run time with EI-AECD #2 active supported

|

—

|

|

EIAECD2_TT_TM1

|

Total run time with EI-AECD #2 Timer 1 active

|

hh:mm:ss

|

|

EIAECD2_TT_TM2

|

Total run time with EI-AECD #2 Timer 2 active

|

hh:mm:ss

|

|

EIAECD3_TT_SUP

|

Total run time with EI-AECD #3 active supported

|

—

|

|

EIAECD3_TT_TM1

|

Total run time with EI-AECD #3 Timer 1 active

|

hh:mm:ss

|

|

EIAECD3_TT_TM2

|

Total run time with EI-AECD #3 Timer 2 active

|

hh:mm:ss

|

|

EIAECD4_TT_SUP

|

Total run time with EI-AECD #4 active supported

|

—

|

|

EIAECD4_TT_TM1

|

Total run time with EI-AECD #4 Timer 1 active

|

hh:mm:ss

|

|

EIAECD4_TT_TM2

|

Total run time with EI-AECD #4 Timer 2 active

|

hh:mm:ss

|

|

EIAECD5_TT_SUP

|

Total run time with EI-AECD #5 active supported

|

—

|

|

EIAECD5_TT_TM1

|

Total run time with EI-AECD #5 Timer 1 active

|

hh:mm:ss

|

|

EIAECD5_TT_TM2

|

Total run time with EI-AECD #5 Timer 2 active

|

hh:mm:ss

|

|

EVAP_SYS_MN

|

Evaporative system monitoring

|

—

|

|

EVAP_SYS_MN_CP

|

Evaporative system monitoring completed

|

—

|

|

FU_SYS_CP

|

Fuel system monitoring completed

|

—

|

|

FU_SYS_ENA

|

Fuel system monitoring enabled

|

—

|

|

FUEL_MCC

|

Fuel monitor completion condition counts

|

— (Undefined/Not Used)

|

|

FUEL_MCEC

|

Fuel monitor conditions encountered counts

|

— (Undefined/Not Used)

|

|

HT_NOX_SRC_MN

|

Heated catalyst monitoring / NOx/SCR aftertreatment monitoring

|

—

|

|

HTR_TANK

|

Urea tank heater

|

Off/On

|

|

IGN_CYCL_CNT

|

Ignition cycle counter

|

— (Undefined/Not Used)

|

|

INTG_D_MFB

|

Integrated dosing mass feedback

|

— (g)

|

|

IP_C_HT_HCU

|

Input current of heater from HCU

|

— (mA)

|

|

LLMD_SIG2_DNOX

|

Linear lambda signal of 2. downstream Nox sensor from CAN

|

—

|

|

MSF_CP

|

Misfire monitoring completed

|

—

|

|

MSF_ENA

|

Misfire monitoring enabled

|

—

|

|

NMHC_C_MCC

|

NMHC catalyst monitor completion counts

|

— (Undefined/Not Used)

|

|

NMHC_C_MCEC

|

NMHC catalyst monitor conditions encountered counts

|

— (Undefined/Not Used)

|

|

NO_DTM_CCT

|

The determined NOx concentration

|

— (ppm)

|

|

NOX_ADS_MCC

|

NOx adsorber monitor completion condition counts

|

— (Undefined/Not Used)

|

|

NOX_ADS_MCEC

|

NOx adsorber monitor conditions encountered counts

|

— (Undefined/Not Used)

|

|

NOX_C_B1S1

|

NOx sensor concentration bank 1 Sensor 1

|

— (ppm)

|

|

NOX_C_B1S1_SUP

|

NOx sensor concentration bank 1 Sensor 1 supported

|

—

|

|

NOX_C_B1S2

|

NOx sensor concentration bank 1 Sensor 2

|

— (ppm)

|

|

NOX_C_B1S2_SUP

|

NOx sensor concentration bank 1 Sensor 2 supported

|

—

|

|

NOX_C_B2S1

|

NOx sensor concentration bank 2 Sensor 1

|

— (ppm)

|

|

NOX_C_B2S1_SUP

|

NOx sensor concentration bank 2 Sensor 1 supported

|

—

|

|

NOX_C_B2S2

|

NOx sensor concentration bank 2 Sensor 2

|

— (ppm)

|

|

NOX_C_B2S2_SUP

|

NOx sensor concentration bank 2 Sensor 2 supported

|

—

|

|

NOX_CCT_ATO1

|

NOx Concentration from ATO1

|

— (ppm)

|

|

NOX_SCR_C_MCC

|

NOx/SCR Catalyst Monitor Completion condition counts

|

— (Undefined/Not Used)

|

|

NOX_SCR_C_MCEC

|

NOx/SCR Catalyst Monitor Conditions encountered counts

|

— (Undefined/Not Used)

|

|

NOX_SIG_ATO1

|

NOx signal status from ATO1

|

—

|

|

NOX_SRC_MN_CP

|

Heated catalyst monitoring completed / NOx/SCR aftertreatment monitoring completed

|

—

|

|

NOX_ST_SEN_SIG

|

Status of NOx sensor signal

|

—

|

|

O2_CCT_ATO1

|

Oxygen Concentration from ATO1

|

—

|

|

O2_SH_PM_F

|

Oxygen sensor heater monitoring / PM filter monitoring

|

—

|

|

O2_SH_PM_F_CP

|

Oxygen sensor heater monitoring completed / PM filter monitoring completed

|

—

|

|

O2_SIG_ST_ATO1

|

Oxygen signal status from ATO1

|

—

|

|

O2_SM_EGSM

|

Oxygen sensor monitoring/exhaust gas sensor monitoring

|

—

|

|

O2_SM_EGSM_CP

|

Oxygen sensor monitoring completed/exhaust gas sensor monitoring completed

|

—

|

|

OBD_MCEC

|

OBD Monitoring conditions encountered counts

|

— (Undefined/Not Used)

|

|

OP_ADC

|

OP of the ADC

|

— (mA)

|

|

OP_F_ACT_PS

|

Output frequency for activation of the power stage

|

— (Hz)

|

|

OP_S_FL_H_MM

|

Output signal of the fill level height in mm

|

— (mm, in)

|

|

PMF_MCC PM

|

Filter monitor completion condition counts

|

— (Undefined/Not Used)

|

|

PMF_MCEC

|

PM filter monitor conditions encountered counts

|

— (Undefined/Not Used)

|

|

PMS_A_B1S1

|

PM sensor active status bank 1 sensor 1

|

—

|

|

PMS_NO_B1S1

|

PM sensor normalized output value bank 1 sensor 1

|

— (%)

|

|

PMS_O_B1S1_SUP

|

PM sensor operating status bank 1 sensor 1 supported

|

—

|

|

PMS_O_B2S1_SUP

|

PM sensor operating status bank 2 sensor 1 supported

|

—

|

|

PMS_R_B1S1

|

PM sensor regen status bank 1 sensor 1

|

—

|

|

PMS_S_B1S1_SUP

|

PM sensor signal bank 1 sensor 1 supported

|

—

|

|

PMS_S_B2S1_SUP

|

PM sensor signal bank 2 sensor 1 supported

|

—

|

|

RDC_PMP_DC_CM

|

Reductant pump duty cycle - commanded

|

—

|

|

RDCT_INJ_DUCY

|

Reductant injector duty cycle

|

%

|

|

RDCT_LINE_HEAT

|

Reductant line heater

|

—

|

|

RDCT_RVDC_CMD

|

Reductant reverting valve duty cycle - commanded

|

%

|

|

RDCT_TANK_HEAT

|

Reductant tank heater

|

—

|

|

RE_TANK_LV

|

Reagent tank level

|

%

|

|

RE_TANK_LV_SUP

|

Reagent tank level supported

|

—

|

|

REDUCT_INJ_DC

|

Reductant injector duty cycle

|

%

|

|

REV_VALVE

|

Urea reverting valve

|

Off/On

|

|

RLA_UR_PMP_PRE

|

Relative DEF pump module pressure

|

— (hPa)

|

|

RMN_DF_TM_PR_L

|

Remaining defrosting time of the pressure line

|

— (s)

|

|

RMN_DF_TM_TK

|

Remaining defrosting time of the tank

|

— (s)

|

|

RMN_ML_DIRC

|

Remaining mileage dircetly based on reducing agent in tank

|

— (km mile)

|

|

RMN_TM_SP_DF

|

Remaining time for supply module defrost

|

— (s)

|

|

RRDC_AG_RMN

|

Remaining quantity of reducing agent

|

— (%)

|

|

S_LLMD_V2_DNOX

|

State of lin lambda value of 2.downstream NOx sensor

|

—

|

|

S_STT_HYD_SCR

|

Substate of hydraulic SCR-system

|

—

|

|

S_UR_TANK_TMP

|

Sensed urea tank temperature

|

°C, °F

|

|

SDARS_BSPR_CP

|

Secondary air system monitoring completed/boost pressure system monitoring completed

|

—

|

|

SDARS_BSTPRE

|

Secondary air system monitoring/boost pressure system monitoring

|

—

|

|

SPDC_URDC

|

Set-point dutycycle from urea dosing controller

|

%

|

|

ST_DF_CHK

|

State of the defrosting check

|

—

|

|

ST_OP_S_PRE_HT

|

Status of output stage pressure heater

|

—

|

|

ST_OP_S_TK_HT

|

Status of output stage tank heater

|

—

|

|

STT_HYD_SCR

|

State of hydraulic SCR-system

|

—

|

|

VOLRDC_AG_RMN

|

Remaining quantity of reducing agent [l]

|

— (l)

|