1. When joining and cutting the new and existing parts, trial fit the new part in position, then measure and adjust the body as necessary to conform with standard dimensions.

2. Drill holes for plug welds before installing new parts.

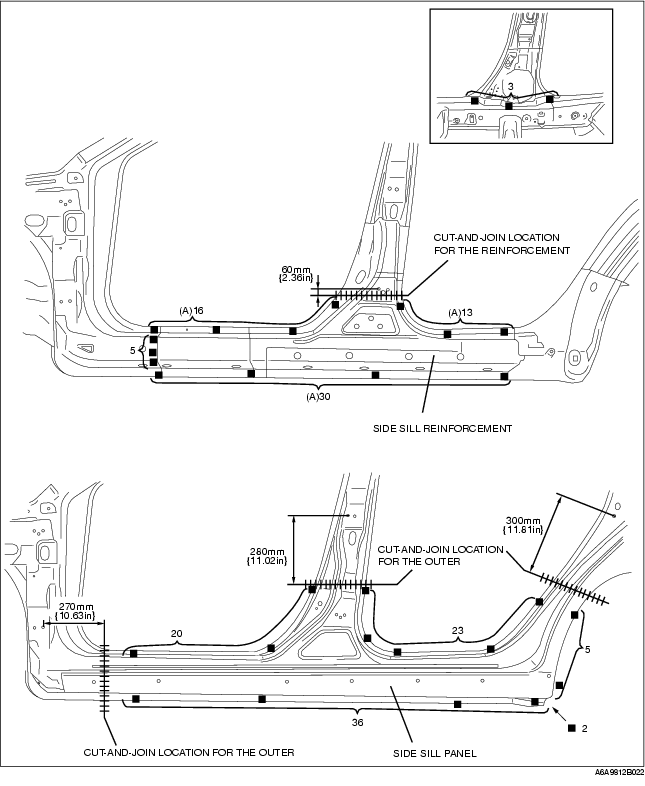

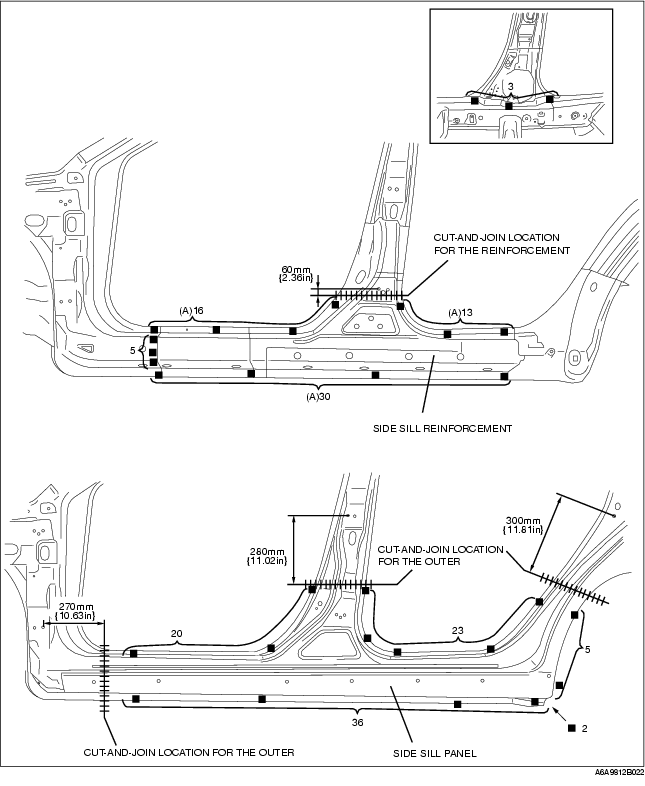

3. Plug welding of 59 weld locations indicated by (A), during installation of the side sill panel.

4. After temporarily installing new parts, make sure the related parts fit properly.

5. Cut out the templates along the cut lines.

6. Face the printed side of the templates to the side step molding, align two sides of the templates, and affix them to the side step molding using double-sided adhesive tape.

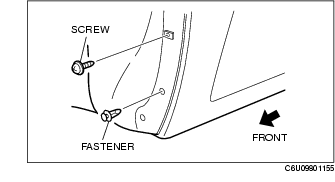

7. Install a screw and fastener.

8. Align the side step molding with the installation position with no clearance with the body, and temporarily fix using a fastener.

9. Align the side step molding bottom surface with the body, press it so that there is no clearance with the body, and temporarily install to the body using tape.

10. Place the templates along the bodyline and affix them using tape.

11. Remove the fastener temporarily fixed in Step 8, and remove the side step molding with the templates affixed to the body.

12. Place the templates along the bodyline and punch holes through the center of the templates.

13. Remove the templates.

14. Wrap packing tape around the drill bit.

15. With the drill bit pointed perpendicular to the body, drill a hole gradually using a ø3 mm {0.12in}, ø6 mm {0.24in}, then ø10mm {0.39in} drill bit.

16. Grind the drilled hole to remove any metal burrs with a round file to finish the surface.

17. Wipe off dirt from the side step molding installation surface on the body using a clean rag dampened with isopropyl alcohol.

18. Apply sealant for rust protection.

19. Apply touch-up paint.