AUTOMATIC TRANSAXLE OUTLINE [JA5AX-EL]

id051705101700

• Use of 3 sets of planetary gears, and a wider gear ratio setting realizes improvement of acceleration-from-standing-start performance, fuel economy, and quietness. Also, by placement of two sets of planetary gears in parallel with one set, the automatic transaxle is more compact.

• Adopted 2-4 brake clutch.

-

- Adopted a wet-type, multi-plate 2-4 brake clutch instead of the 2-4 brake band used in the past, for smoother gear switching performance.

• Adopted centrifugal balance clutch

-

- The newly adopted centrifugal balance clutch pushes the clutch piston forcefully to low and high clutch by centrifugal hydraulic pressure for smoother gear switching with batter response.

• Adopted controller area network (CAN)

-

- By adopting CAN, The TCM is always in contact with other computers in the car and controls the automatic transaxle properly. This has also made troubleshooting diagnosis easier for the entire vehicle.

• Solenoid, sensor

-

- Adoption of four duty-type solenoids, five ON-OFF type solenoids, and three revolving sensors realizes finer, more expedient control of gear shifting performance.

• Adoption of revers inhibit control

-

- If the reverse position is selected by mistake while driving in forward motion, the reverse inhibit control system will cancel the operation electronically and set the position to neutral as a safety enhancement.

Outline of Operation

• The operation of the electronic automatic transaxle is classified into three systems: the electronic control system, the hydraulic pressure control system, and the powertrain system (includes the torque converter system.)

-

Electronic control system

-

• According to the signals from the switches and sensors in the input system, the TCM outputs the signal which matches the present driving condition to the ON/OFF type solenoids and the duty-cycle type solenoids in the hydraulic pressure control system.

-

Hydraulic pressure control system

-

• According to the signals from the TCM, each solenoid operates to switch the hydraulic passages in the control valve body and controls the clutch engagement pressure.

-

• The line pressure is adjusted by the duty-cycle type pressure control solenoid. The hydraulic passages are switched by the ON/OFF type solenoids and the clutch engagement pressure is controlled by the duty-cycle type solenoids.

-

Powertrain system

-

• The driving force from the engine is transmitted through the torque converter to the transaxle.

-

• The transmitted driving force operates each clutch and brake according to the clutch engagement pressure from the duty-cycle type solenoid, and the planetary gears change the gear ratio to the optimal driving force. The changed driving force is transmitted through the differential to the axle shaft and then the tires.

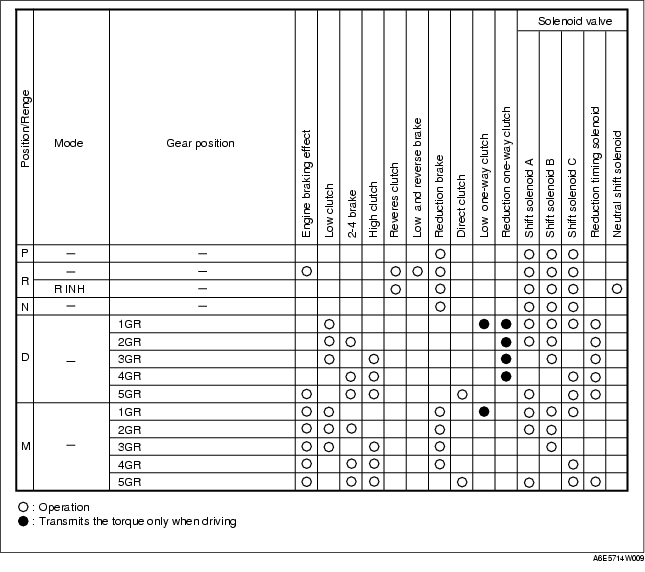

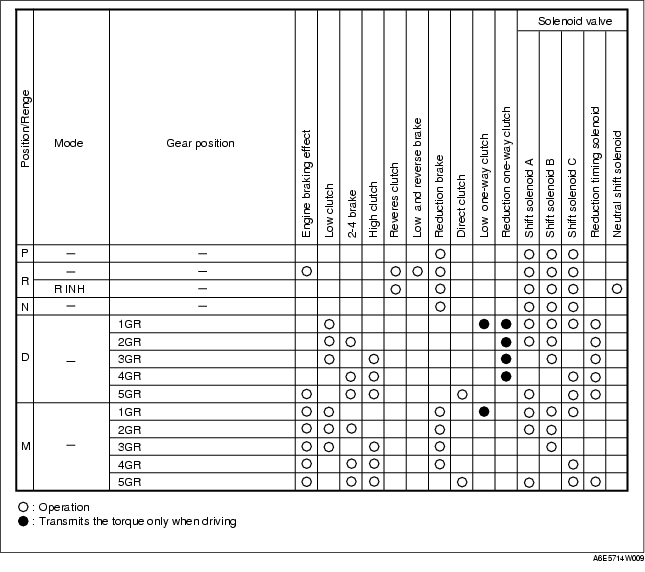

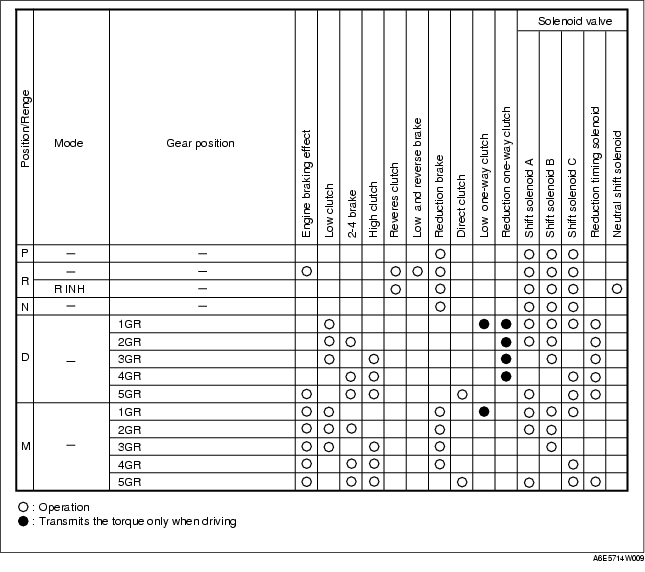

EC-AT Operation Chart