CRANKSHAFT, MAIN BEARING CONSTRUCTION [LF, L3]

id0110001008a2

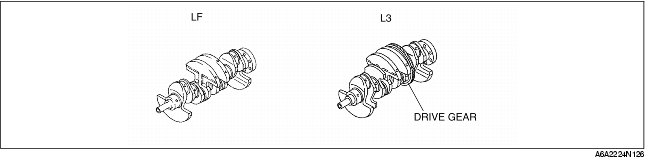

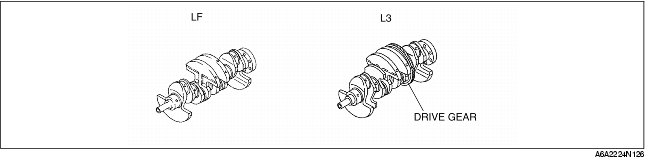

• A 5-axle hole, 4-counter weight cast iron LF engine model crankshaft has been adopted.

• A 5-axle hole, 8-counter weight cast iron L3 engine model crankshaft has been adopted. The shrinkage fitted drive gear is attached to the crankshaft and the crankshaft drives the balance shaft.

• There is no positioning key where the crankshaft sprocket and crankshaft pulley are installed. The crankshaft sprocket must be installed using the SST with the No.1 cylinder aligned with the TDC position. Tightening pressure on the tightening bolt is used to secure the crankshaft sprocket and crankshaft pulley.

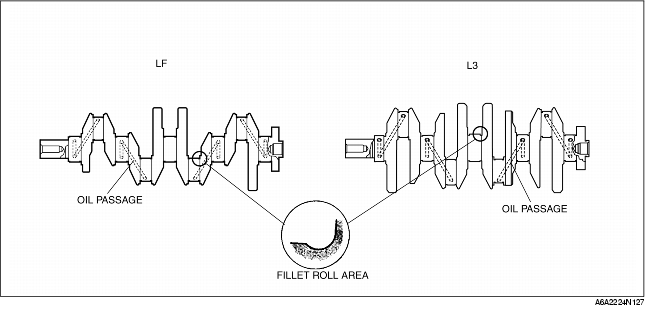

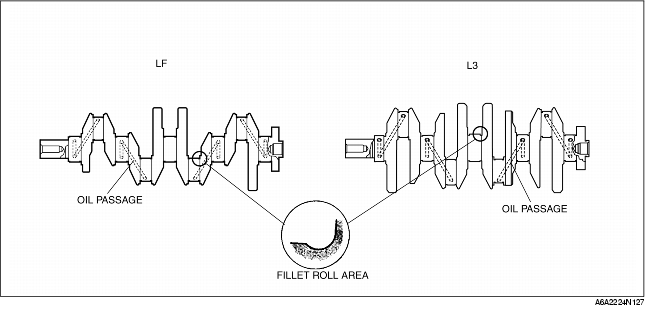

• An oil line for supplying oil to each journal is provided in the crankshaft. Crank pins and fillets on both sides of the journal are rolled to bear heavy loads.

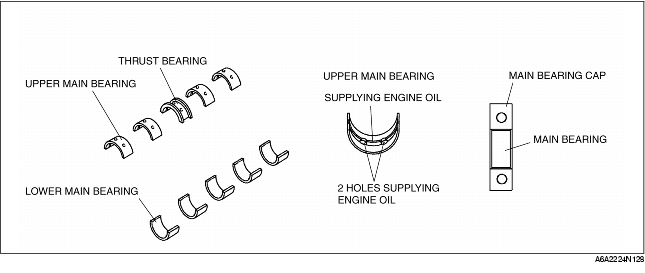

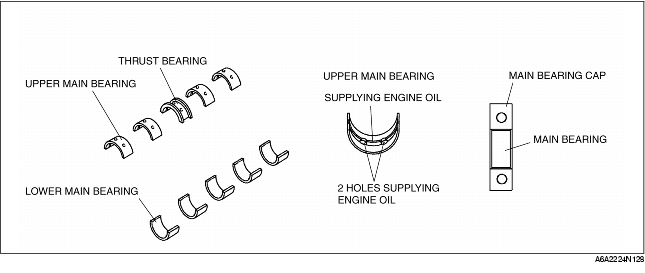

• Upper and lower main bearings are made of aluminum alloy and the upper side No.3 journal bearing is integrated with the thrust bearing. The upper main bearing has oil grooves and oil holes.

• There is no upper and lower bearings' positioning tab for installing the main journal.

• Measure and attach the main bearings (upper of and lower) so that they are positioned at the center of the main bearing cap.

• Three kinds of main bearings are available depending on the oil clearance.

|

Bearing size

|

Bearing thickness (mm {in})

|

|

Standard

|

2.506-2.509 {0.0987-0.0988}

|

|

0.25 {0.01} Oversize

|

2.628-2.634 {0.1035-0.1037}

|

|

0.50 {0.02} Oversize

|

2.753-2.759 {0.1084-0.1086}

|