ENGINE MOUNT CONSTRUCTION [LF, L3]

id0110001140a2

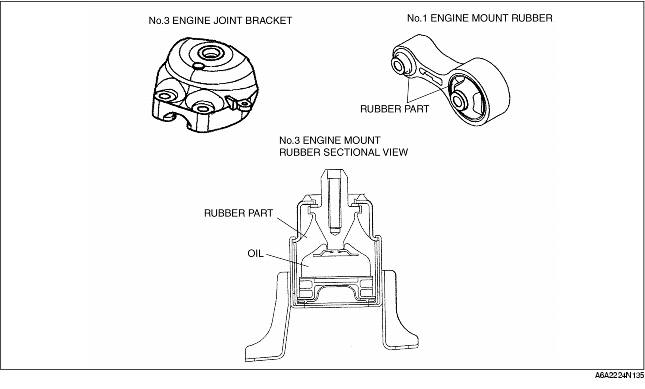

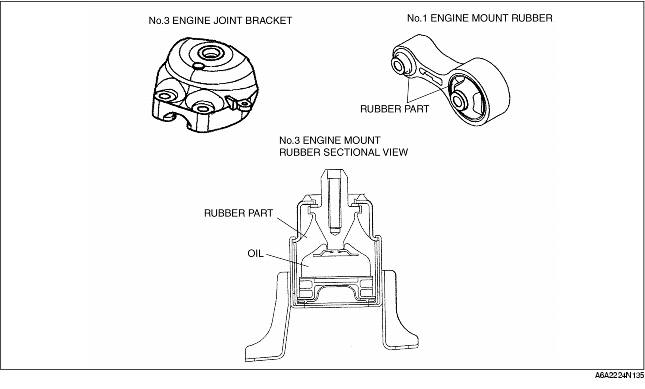

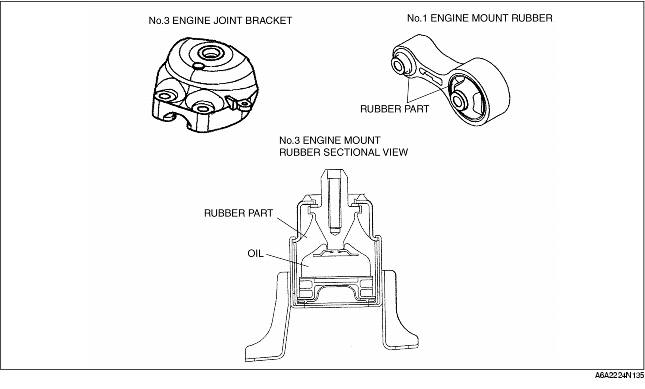

• The exterior frame of the No.1 engine mounting rubber is made of aluminum alloy, and is composed of a torque rod-shaped structure including an anti-vibration function, which regulates the conventional rubber function and the rotation from the powertrain.

• The No.3 engine mounting rubber is oil-filled for noise reduction and vibration isolation.

• The No.3 engine-mounting bracket is integrated with the aluminum alloy engine front cover.

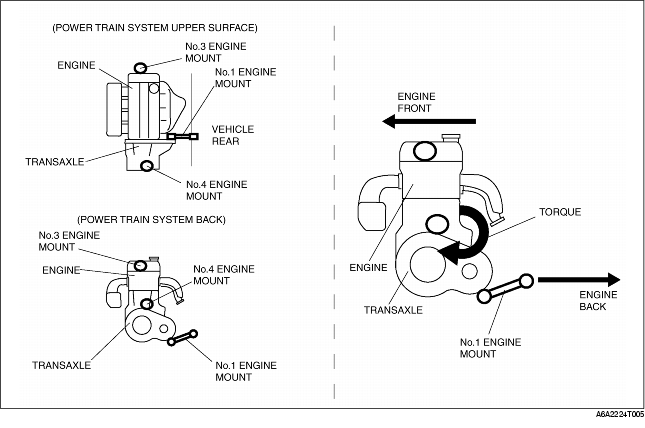

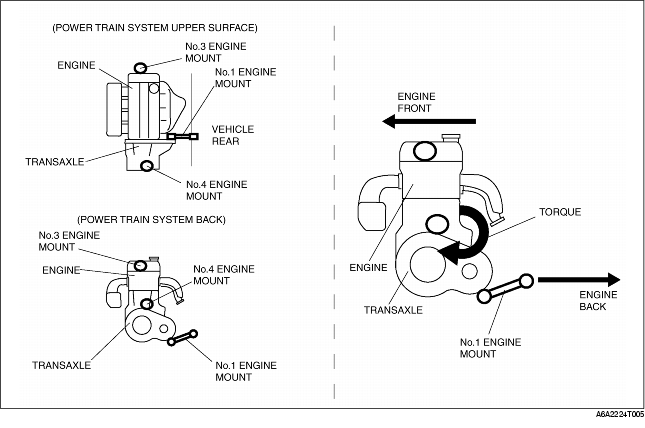

• The engine is supported at the following three points: front part of the engine (No.3 engine mounting), one side of the transaxle (No.1 engine mounting), and rear upper part of the transaxle (No.4 engine mounting). The supporting point at the side of the transaxle (No.1 engine mounting) has been set at the transaxle's lowest edge. With this layout, the No.1 engine mounting absorbs the rotation force generated under engine torque fluctuation and transmitted to the power train, and distributes the rotation force to the front and rear part of the engine (swing bob).