OIL PRESSURE INSPECTION [LF, L3]

id0111008003b5

-

Warning

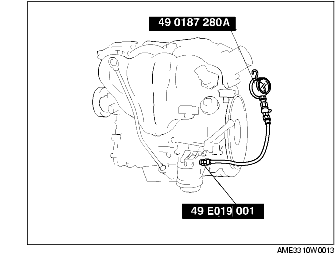

-

• Continuous exposure to USED engine oil has caused skin cancer in laboratory mice. Protect your skin by washing with soap and water immediately after working with engine oil.

-

• Hot engines and engine oil can cause severe burns. Turn off the engine and wait until it and the engine oil have cooled.

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Remove the oil pressure switch.

4. Screw the SST into the oil pressure switch installation hole.

5. Warm up the engine to normal operating temperature.

6. Run the engine at the specified speed, and note the gauge readings.

-

• If the pressure is not as specified, inspect for the cause and repair or replace if necessary.

-

Note

-

• The oil pressure can vary with oil viscosity and temperature.

-

Oil pressure (reference value) [oil temperature: 100°C {212°F}]

-

LF: 234-521 kPa {2.39-5.31 kgf/cm2, 33.9-75.5 psi} min [3,000rpm]

-

L3: 395-649 kPa {4.03-6.61 kgf/cm2, 57.3-94.1 psi} min [3,000rpm]

7. Stop the engine and wait until it is cool.

8. Remove the SST.

-

Caution

-

• Any sealant stuck at the end of the oil pressure switch can cause operation malfunction of the oil pressure switch.

-

Be sure there is no sealant at the end of the oil pressure switch.

9. Apply silicone sealant to the oil pressure switch threads as shown.

10. Install the oil pressure switch.

-

Tightening torque

-

12-18 N·m {1.2-1.8 kgf·m, 9-13 ft·lbf}

11. Install the under cover.

12. Start the engine and inspect for oil leakage.

-

• If the oil leaks, specify the faulty part and repair or replace it.