|

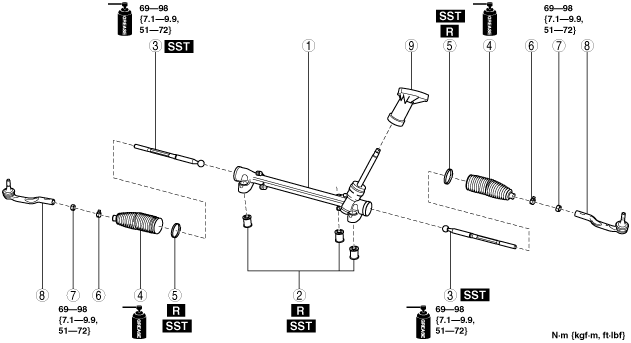

STEERING GEAR AND LINKAGE ASSEMBLY

id061300802100

1. Assemble in the order shown in the figure.

L.H.D.

am6zzw00009182

|

R.H.D.

am6zzw00009183

|

|

1

|

Steering gear

|

|

2

|

Mounting rubber

|

|

3

|

Tie rod

(See Tie Rod Assembly Note .)

|

|

4

|

Boot

|

|

5

|

Boot band

(See Boot Band Assembly Note .)

|

|

6

|

Boot clamp

|

|

7

|

Locknut

|

|

8

|

Tie-rod end

(See Tie-rod End Assembly Note.)

|

|

9

|

Dust cover

|

Mounting Rubber Assembly Note

1. Apply soapy water to the rubber part of the mounting rubber.

2. Press fit the ear portion of the mounting rubber (lower side) using the SSTs until it projects from the gear housing as shown in the figure.

am6zzw00009184

|

3. Reverse the gear housing, then press fit the mounting rubber using the SSTs and the press until the mounting rubber ear portion (upper side) contacts the gear housing.

am6zzw00009185

|

4. Verify that both mounting rubber ears are correctly assembled with no gaps between them and the gear housing as shown in the figure.

am6zzw00009186

|

Tie Rod Assembly Note

1. Lock the steering rack end (pinion gear side) against rotation with a wrench and install the tie rod using the suitable wrench.

ac5wzw00001045

|

2. Combine the SST with the torque wrench, then measure A and L as shown in the figure.

am6zzw00012603

|

3. Recalculate the torque by using torque formulas, then tighten the tie rod using the SST.

ac5wzw00005624

|

Torque formula

|

Torque unit |

Formula |

|---|---|

|

N·m

|

N·m×[L/A]

|

|

kgf·m

|

kgf·m×[L/A]

|

|

ft·lbf

|

ft·lbf×[L/A]

|

Boot Band Assembly Note

1. Assemble the boot band to the boot.

2. Crimp the boot band using the SST.

ac5wzw00001046

|

3. Verify that the crimping clearance A is within the specification.

4. Rotate the by hand and verify that it is securely installed to the boot band.

Tie-rod End Assembly Note

1. Align the alignment marks made before removal and assemble the tie-rod end to the tie rod.

am6zzw00009164

|

am6zzw00009187

|

2. Adjust dimension A shown in the figure to the standard, then assemble the tie-rod end.

am6zzw00009188

|