|

am6zzn00003260

AIM OF DEVELOPMENT

id000000100100

Product Concept

Vehicle Outline

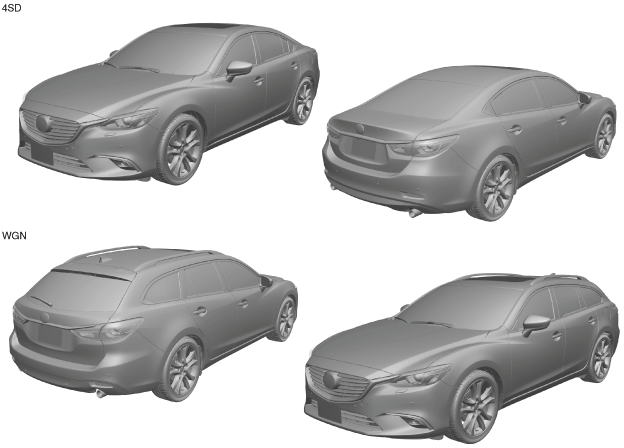

Exterior design

External view

am6zzn00003260

|

Interior design

am6zzn00003261

|

Engine

Suspension

ac5wzn00001047

|

2WD

ac5uun00000310

|

4WD

ac5uun00000311

|

Driveline/axle

Brakes

Vehicle front side (L.H.D.)

am6zzn00003859

|

Vehicle front side (R.H.D.)

am6zzn00003860

|

Vehicle rear side

am6zzn00003861

|

Vehicle front side (L.H.D.)

am6zzn00003208

|

Vehicle front side (R.H.D.)

am6zzn00003209

|

Vehicle rear side

am6zzn00003210

|

Transaxle

ac5wzn00001054

|

ac5wzn00001738

|

ac5wzn00001055

|

ac5jjn00001299

|

Steering

L.H.D. (Without Lane-Keep Assist System)

am6zzn00003216

|

L.H.D. (With Lane-Keep Assist System)

am6zzn00003217

|

R.H.D. (Without Lane-Keep Assist System)

am6zzn00003218

|

R.H.D. (With Lane-Keep Assist System)

am6zzn00003219

|

Safety

Driver's support