|

am3uun00002434

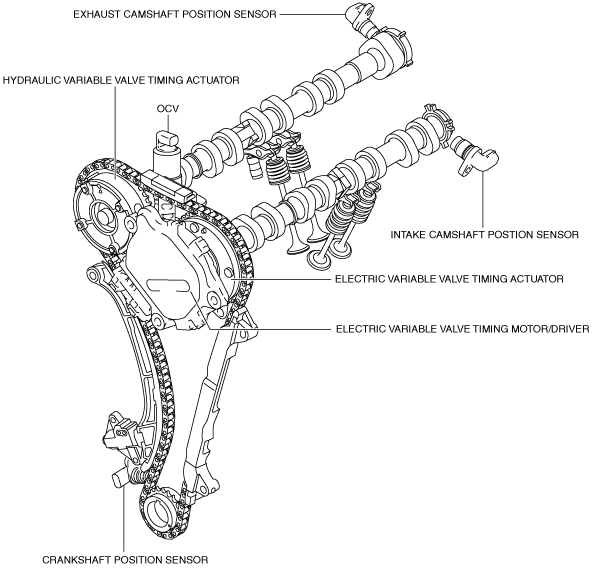

VARIABLE VALVE TIMING MECHANISM [SKYACTIV-G 2.0, SKYACTIV-G 2.5]

id0110h3002000

Outline

Structural View

am3uun00002434

|

Structure

|

Part name

|

Function

|

|

Hydraulic variable valve timing actuator

|

The hydraulic variable valve timing actuator operates according to the hydraulic pressure and changes the phases of the exhaust camshaft.

|

|

Electric variable valve timing actuator

|

The electric variable valve timing actuator changes the phases of the intake camshaft.

|

|

Electric variable valve timing motor/driver

|

Operates the electric variable valve timing actuator based on the signals from the PCM.

|

|

OCV

|

Operated by current (duty signal) from the PCM. Controls the hydraulic oil passages to the variable valve timing actuator.

|

|

Intake camshaft position sensor

|

Sends the intake camshaft position signal to the PCM.

|

|

Exhaust camshaft position sensor

|

Sends the exhaust camshaft position signal to the PCM.

|

|

Crankshaft position sensor

|

Sends the crankshaft position signal to the PCM.

|

Operation

At engine start

Light/medium load range

High load range