|

1

|

INSPECT POWER SUPPLY (SYSTEM) CIRCUIT

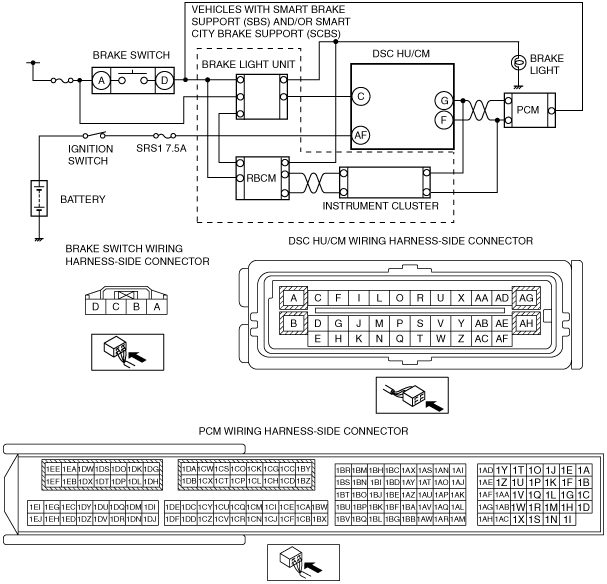

• Measure the voltage at the DSC HU/CM connector terminal AF (vehicle harness side) and body ground.

-

― Ignition switch OFF: 1 V or less

― Ignition switch ON (engine off): B+

• Is the voltage normal?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between ignition switch and DSC HU/CM terminal AF (vehicle harness side).

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a open circuit.

Go to Step 8.

|

|

2

|

VERIFY OPEN OR SHORT CIRCUIT IN BRAKE SWITCH SIGNAL

• Measure the voltage between the PCM connector terminal 2G (SKYACTIV-G 2.0/SKYACTIV-G 2.5)/2AA (SKYACTIV-D 2.2) (vehicle harness-side) and body ground when the brake pedal is depressed and released.

-

― Brake pedal depressed: B+

― Brake pedal released: 1 V or less

• Is the voltage normal?

|

Yes

|

Go to the Step 8.

|

|

No

|

If it is B+ under any condition, then go to the next step.

If it is 1 V or less under any condition, then go to Step 4.

|

|

3

|

INSPECT BRAKE SWITCH SIGNAL FOR SHORT TO POWER SUPPLY CIRCUIT

• Disconnect the brake switch connector.

• Measure voltage between the brake switch connector terminal D (vehicle harness-side) and body ground.

• Is the voltage 1 V or less?

|

Yes

|

Go to Step 4.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between PCM connector terminal 2G (SKYACTIV-G 2.0/SKYACTIV-G 2.5)/2AA (SKYACTIV-D 2.2) (vehicle harness-side) and brake switch connector terminal D (vehicle harness side).

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to power supply.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to power supply.

Go to Step 8.

|

|

4

|

INSPECT BRAKE SWITCH SIGNAL FOR OPEN CIRCUIT

• Disconnect the PCM connectors.

• Inspect continuity between the PCM and brake switch as follows.

-

― SKYACTIV-G 2.0/SKYACTIV-G 2.5

-

• PCM connector terminal 2G (vehicle harness-side) and brake switch connector terminal D (vehicle harness-side)

― SKYACTIV-D 2.2

-

• PCM connector terminal 2AA (vehicle harness-side) and brake switch connector terminal D (vehicle harness-side)

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between PCM connector terminal 2G (SKYACTIV-G 2.0/SKYACTIV-G 2.5)/2AA (SKYACTIV-D 2.2) (vehicle harness-side) and brake switch connector terminal D (vehicle harness side).

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 8.

|

|

5

|

INSPECT BRAKE SWITCH

• Inspect the brake switch.

• Is the brake switch normal?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the brake switch, then go to Step 8.

|

|

6

|

VERIFY REAR BODY CONTROL MODULE (RBCM) DTC

• Using the M-MDS, perform the rear body control module (RBCM) DTC inspection.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

DTC troubleshooting completed, then go to Step 8.

|

|

No

|

Go to the next step.

|

|

7

|

VERIFY PCM DTC

• Using the M-MDS, perform the PCM DTC inspection.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

DTC troubleshooting completed, then go to the next step.

|

|

No

|

Go to the next step.

|

|

8

|

VERIFY DTC TROUBLESHOOTING COMPLETED

• Using the M-MDS, clear the DTC from the DSC HU/CM.

• Start the engine and drive the vehicle at 20 km/h {12 mph} or more.

• Gradually slow down and stop vehicle.

• Using the M-MDS, perform the DSC HU/CM DTC inspection.

• Is the same DTC present?

|

Yes

|

Repeat the inspection from Step1.

|

|

No

|

Go to the next step.

|

|

9

|

VERIFY NO DTC IS PRESENT

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|