|

am6zzn00001174

AIM OF DEVELOPMENT

id000000100100

Product Concept

Unrivaled styling and performance

Vehicle Outline

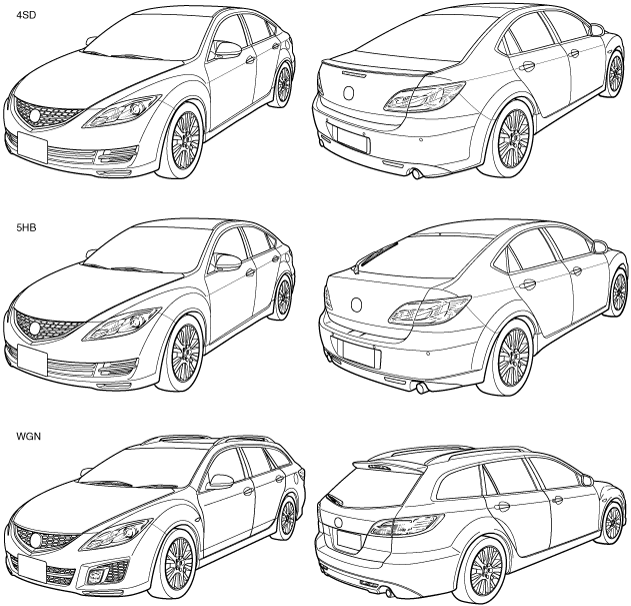

Exterior

External View

am6zzn00001174

|

Interior

am6zzn00001432

|

Engine

Suspension

am6zzn00001356

|

am6zzn00000639

|

Brakes

L.H.D.

am6zzn00001433

|

R.H.D.

am6zzn00001434

|

Antilock brake system (ABS)

L.H.D.

am6zzn00000156

|

R.H.D.

am6zzn00000170

|

Dynamic stability control (DSC)

L.H.D.

am6zzn00001428

|

R.H.D.

am6zzn00001429

|

Transaxle

am6zzn00000265

|

am6zzn00000278

|

am6zzn00001176

|

am6zzn00000799

|

Power Steering

L.H.D.

am6zzn00001472

|

R.H.D.

am6zzn00000249

|

Safety