DTC P062A:00

Suction control valve circuit range/performance malfunction

DETECTION CONDITION

• The PCM monitors the suction control valve circuit current while the engine is running. If the PCM detects the circuit current is less than 1 A when the suction control valve is on, the PCM determines that there is a malfunction in the suction control valve circuit.

• The PCM monitors the suction control valve circuit current while the engine is running. If the PCM detects circuit current is more than 1 A when the suction control valve is off, the PCM determines that there is the malfunction in the suction control valve circuit.

-

― Following conditions are met:

-

• Battery voltage: 8—20 V• Engine speed: more than 0 rpm (at running)• Suction control valve driving duty: 100 %

-

Monitoring conditions

Diagnostic support note

• The MIL illuminates if the PCM detects the above malfunction condition in first drive cycle.

• PENDING CODE is available if the PCM detects the above malfunction condition during the first drive cycle.

• FREEZE FRAME DATA is available.

• The DTC is stored in the PCM memory.

POSSIBLE CAUSE

• Suction control valve connector or terminal malfunction

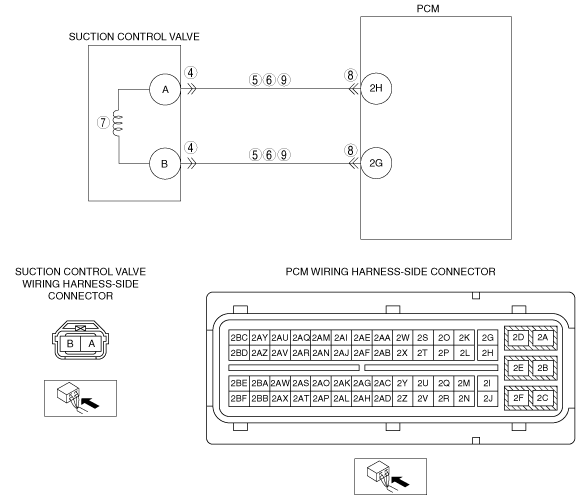

• Short to power supply in wiring harness between suction control valve terminal A and PCM terminal 2H

• Short to power supply in wiring harness between suction control valve terminal B and PCM terminal 2G

• Short to ground in wiring harness between suction control valve terminal A and PCM terminal 2H

• Short to ground in wiring harness between suction control valve terminal B and PCM terminal 2G

• Suction control valve malfunction

• PCM connector or terminal malfunction

• Open circuit in wiring harness between suction control valve terminal A and PCM terminal 2H

• Open circuit in wiring harness between suction control valve terminal B and PCM terminal 2G

• PCM malfunction