|

OIL PRESSURE INSPECTION [L8, LF, L5]

id0111c3800300

1. Disconnect the negative battery cable.

2. Remove the aerodynamic under cover No.2. (See AERODYNAMIC UNDER COVER NO.2 REMOVAL/INSTALLATION.)

3. Remove the oil pressure switch.

4. Remove the clutch release cylinder with the clutch pipe still connected so that the SSTs are installed. (MTX) (See MANUAL TRANSAXLE REMOVAL/INSTALLATION [G35M-R].) (See MANUAL TRANSAXLE REMOVAL/INSTALLATION [G66M-R].)

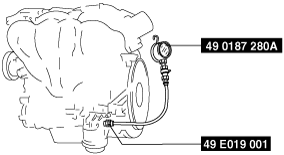

5. Screw the SSTs into the oil pressure switch installation hole.

am6zzw00002309

|

6. Connect the negative battery cable.

7. Start the engine while the rod of the starter interlock switch which is installed to the clutch pedal is completely pushed toward the arrow shown in the figure using a flathead screwdriver or equivalent. (MTX equipped with starter interlock switch)

am6zzw00002836

|

8. Warm up the engine to normal operating temperature.

9. Run the engine at the specified speed, and note the gauge readings.

10. Stop the engine and wait until it is cool.

11. Disconnect the negative battery cable.

12. Remove the SSTs.

13. Apply silicone sealant to the oil pressure switch threads as shown in the figure.

am6zzw00002310

|

14. Install the oil pressure switch.

15. Install the clutch release cylinder. (MTX) (See MANUAL TRANSAXLE REMOVAL/INSTALLATION [G35M-R].) (See MANUAL TRANSAXLE REMOVAL/INSTALLATION [G66M-R].)

16. Connect the negative battery cable.

17. Start the engine and confirm that there is no oil leakage.

18. Install the aerodynamic under cover No.2. (See AERODYNAMIC UNDER COVER NO.2 REMOVAL/INSTALLATION.)