|

be13ze00000001

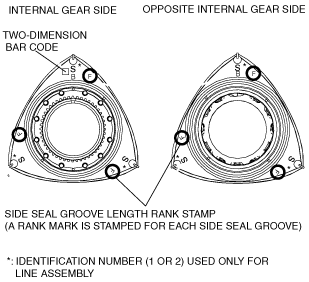

SIDE SEAL INSPECTION

id011000132200

Replacing With A New Side Seal

1. If replacing the side seal, select the appropriate side seal from the side seal groove length rank marked on the rotor.

be13ze00000001

|

Side seal selection table

|

Side seal groove length rank stamp |

Part number of side seal |

|---|---|

|

F

|

N3Z1 11 C10*

|

|

G

|

|

|

H

|

|

|

I

|

|

|

J

|

N3Z2 11 C10*

|

|

K

|

|

|

L

|

|

|

M

|

|

|

N

|

N3Z3 11 C10*

|

|

O

|

|

|

P

|

|

|

Q

|

|

|

R

|

N3Z4 11 C10*

|

|

S

|

|

|

T

|

|

|

U

|

|

|

V

|

N3Z5 11 C10*

|

|

W

|

|

|

X

|

|

|

Y

|

Reusing The Side Seal

1. Measure the side seal and corner seal clearance and verify that it doesn’t exceed the maximum.

be13ze00000002

|