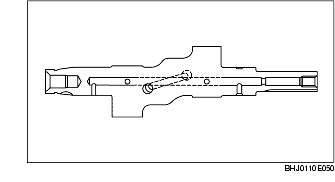

ECCENTRIC SHAFT INSPECTION

id011000133600

1. Inspect for clogging in the oil passage.

-

• If there is any clogging, remove it with a needle or similar device and clean with compressed air.

2. After setting the eccentric shaft main journal on V-blocks and a surface plate, measure the runout at the end of the eccentric shaft using a dial gauge.

-

• If it exceeds the maximum specification, replace the eccentric shaft.

-

Standard runout

-

0.02 mm {0.0008 in}

-

Maximum runout

-

0.06 mm {0.0024 in}