OIL PUMP INSPECTION

id011000505300

Type A

1. Measure the body clearance between the outer rotor and the body using a feeler gauge.

-

• If it exceeds the maximum specification, replace the oil pump.

-

Standard body clearance

-

0.20—0.25 mm {0.0079—0.0098 in}

-

Maximum body clearance

-

0.3 mm {0.0118 in}

2. Measure the tip clearance between the inner rotor and the outer rotor using a feeler gauge.

-

• If it exceeds the maximum specification, replace the oil pump.

-

Standard tip clearance

-

0.03—0.12 mm {0.0012—0.0047 in}

-

Maximum tip clearance

-

0.15 mm {0.0059 in}

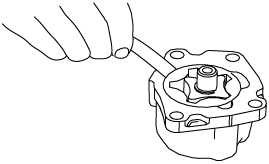

3. Measure the side clearance between the rotor and the side housing using a straight edge and a feeler gauge.

-

• If it exceeds the maximum specification, replace the oil pump.

-

Standard side clearance

-

0.03—0.125 mm {0.0012—0.0049 in}

-

Maximum side clearance

-

0.15 mm {0.0059 in}

Type B

-

Note

-

• The oil pump cannot be disassembled because it is a precision unit. If a malfunction occurs, replace the oil pump component as a single unit.

1. Visually inspect the oil pump gasket.

-

• Replace the oil pump component if the condition corresponds to any one of the following:

-

― The lip is damaged.

― The lip and the metallic outer ring are at the same level.