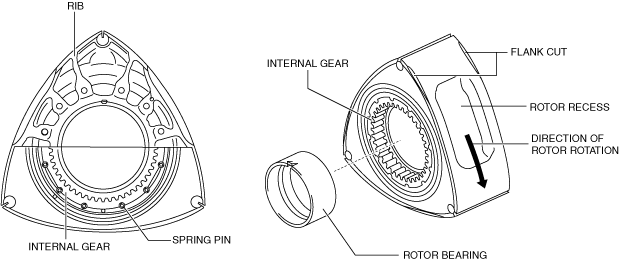

ROTOR CONSTRUCTION [13B-MSP]

id011070660400

• A hollow rotor has been adopted for weight reduction.

• A rib has been equipped inside the rotor to heighten the rigidity.

• The outer surfaces of the rotor include rotor recesses that serve as the combustion chambers. (Bathtub shape)

• A rotor bearing has been installed to the interior wall of the central axial area because the wall rubs against the eccentric shaft.

• The internal gear is engaged with the stationary gear to provide proper rotational force to the rotor.

• The spring pin reduces the load applied to the gears when the internal and stationary gears are engaged.

• Flank cuts are located at the corners of the rotor to delay exhaust closing timing by approx. 15 degrees, improving exhaust efficiency.