|

OIL PAN REMOVAL/INSTALLATION [13B-MSP]

id0111e4800200

1. Remove the engine cover. (See ENGINE COVER REMOVAL/INSTALLATION [13B-MSP].)

2. Drain the engine oil. (See ENGINE OIL REPLACEMENT [13B-MSP].)

3. Remove the under cover. (See OIL FILTER REPLACEMENT [13B-MSP].)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

6. Refill with the specified type and amount of the engine oil. (See ENGINE OIL REPLACEMENT [13B-MSP].)

7. Start the engine and confirm that there is no oil leakage.

8. Inspect the oil level. (See ENGINE OIL LEVEL INSPECTION [13B-MSP].)

ar8wzw00000733

|

|

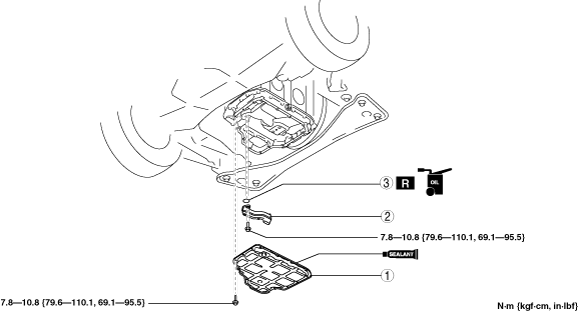

1

|

Oil pan

(See Oil Pan Removal Note.)

(See Oil Pan Installation Note.)

|

|

2

|

Oil strainer

|

|

3

|

O-ring

|

Oil Pan Removal Note

1. Remove the oil pan using a separator tool.

am6zzw00002303

|

Oil Pan Installation Note

am6zzw00002304

|

1. Completely clean and remove any oil, dirt, sealant or other foreign material that may be adhering to the oil pan upper block and oil pan.

2. When reusing the oil pan installation bolts, clean any old sealant from the bolts.

3. Apply silicone sealant to the areas as shown in the figure.

ar8wzw00000734

|

4. Install the oil pan to the oil pan upper block.

5. Tighten the oil pan installation bolts.